Product Overview

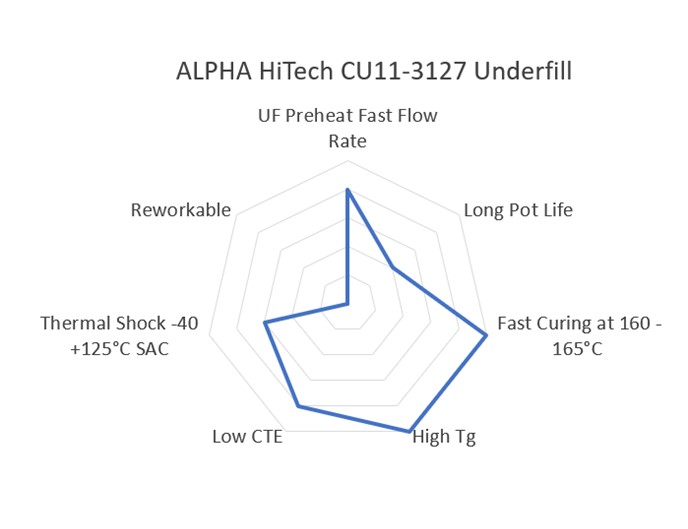

ALPHA HiTech CU11-3127, a product with high filler content, is available to provide better mechanical strength for CSP and Flip Chip packages.

ALPHA HiTech CU11-3127 has a unique low viscosity property, making it possible to secure full coverage flow at room temperature without preheat. For a faster flow rate, preheat of < 80°C is recommended on substrates during dispensing process.

Product Features

- Enabling fast and efficient flow properties at high temperature but must be <80°C

- Releases stress over a large area, primary stress is CTE mismatch between component and board

- High Glass Transition Temperature

- Low Coefficient of Thermal Expansion

- Halogen Free Complies with RoHS Directive 2011/65/EU

Underfill For Exceptional Thermal Fatigue Resistance

Stand alone SAC solder joints in BGA and CSP assemblies tend to falter in thermally harsh automotive applications. High Tg and low CTE underfill [UF] is a reinforcement solution. ALPHA HiTech CU11-3127 has a high Tg of 177°C and low CTE1 of 29 ppm. Rework not a requirement allows higher filler content in formulation to develop such attributes. While it is possible to secure complete coverage during dispensing at 25°C, preheating the substrates, not more than 80°C, during dispensing can significantly improve the flow rate.