Product Overview

Our immersion silver final finishes are trusted by hundreds of fabricators, assembly houses, and OEMs worldwide. These finishes have exceptional solder joint strength, touchpad functionality, and aluminum wire bondability, making them an excellent general purpose final finish for standard printed circuit boards.

Product Features

- Specified by fabricators, assemblers and OEM’s worldwide

- Exceptional solder joint strength, touchpad functionality and wire bondability

- Superior conductivity for ultra-high RF applications

- An effective solution for black pad, tin whiskers and exposed copper

Our immersion silver final finishes are trusted by hundreds of fabricators, assembly houses, and OEMs worldwide.

AlphaSTAR Sales Sheet (EN)

Sterling Sales Sheet (EN)

Electroless Nickel - Immersion Silver: A New Surface Finish for Pcb Applications Technical Publication SMTAI 2012 (EN)

PCB Surface Finishes Technical Publication SMTNet 2015 (EN)

Silver & Change: A Tale of Silver, Copper, Nickel, and Gold Technical Publication PCB007 2015 (EN)

Sterling®

MacDermid Enthone's Sterling immersion silver finish provides exceptional solder joint strength, touchpad functionality, wire bondability, and in-circuit test compatibility. Benefits are achieved throughout the supply chain. Fabricators receive a versatile solution that can be applied with either horizontal or vertical equipment. Assemblers benefit from a durable finish that performs through multiple heat excursions, and high yields due to complete flux and paste compatibility. OEM’s gain uncontested reliability and service life due to the resulting copper/tin solder joint.

From automotive to computers, military to communications, Sterling is one of the top choices of OEM’s worldwide. Sterling provides high assembly yields, excellent contact functionality, and predictable solderability with multiple reflows. It is also wire-bondable, resulting in ultimate assembly flexibility.

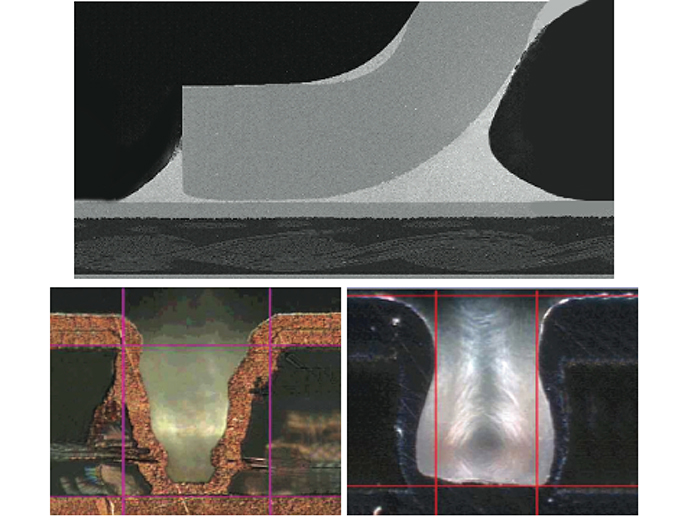

Sterling consistently delivers strong and durable solder joints. During soldering, the thin silver finish dissolves entirely into the bulk solder, resulting in a reliable and resilient copper/tin solder joint. Sterling’s reliable and consistent silver plating in blind microvias meets today's complex technological demands, and enables maximum utilization of circuit board real estate.

AlphaSTAR®

AlphaSTAR is an industry-leading tarnish-resistant immersion silver process that eliminates planar microvoids while preventing creep and flaking corrosion. The process meets the most complex lead-free assembly, end use performance and application requirements as mandated by the world’s leading OEMs, PCB assemblers and fabricators. AlphaSTAR selectively deposits a consistent and reliable high performance silver coating that delivers exceptional first-pass yields at the lowest cost of ownership versus traditional metallic processes. The AlphaSTAR process does not require an anti-tarnish, allowing for a reduced equipment footprint and rework costs.