Product Overview

MacDermid Alpha understands the challenges of providing conductor shapes that exceed your customers’-controlled impedance requirements, while reliably bonding to next-generation dielectrics for lead-free, low-loss applications. As new materials continue to evolve in this space, MacDermid Alpha will deliver processes for the wide range of specialty applications in IC substrate manufacturing. As the demonstrated market leader in the development of high reliability bonding conversion coatings and precision etches for all substrate applications, let MacDermid Alpha provide you with the solution you need.

Product Features

- Anisotropic final etch with minimal undercut and square circuit profile

- Copper adhesion promotion for high speed applications

- Laser direct drilling oxide coating for improved consistency of drilling process

As the demonstrated market leader in the development of high reliability bonding conversion coatings and precision etches for all substrate applications, let MacDermid Alpha provide you with the solution you need.

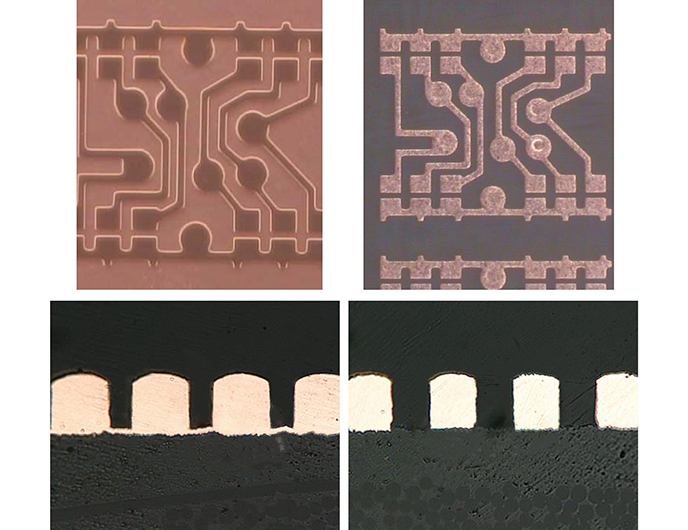

Anisotropic Final Etching Process

In the final etch that removes the copper foil in mSAP processing or the electrolytic copper seed layer in SAP processing, it is crucial to limit the lateral etching of the trace. The CircuEtch 300 process is a high-performance peroxide-sulfuric etchant system that ensures maximum circuit densities, trace profile, and excellent adhesion. CircuEtch 300 features an easy to maintain bath that has a highly stable etching rate for predictable performance and process consistency.

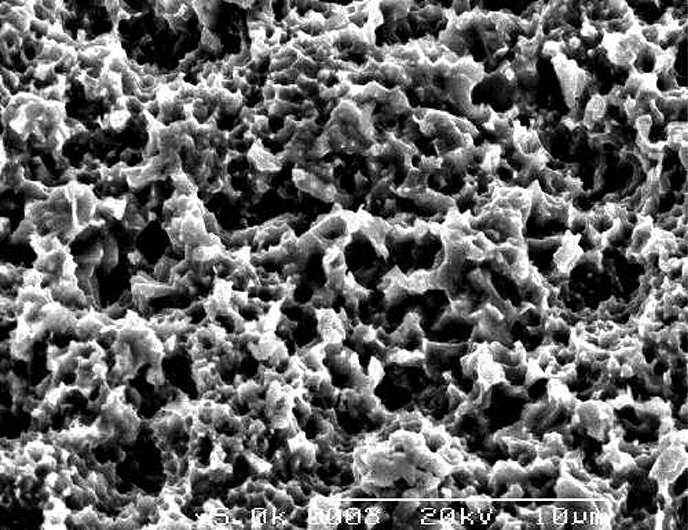

Copper Adhesion Promotion

MultiPrep 200 is a unique pretreatment process that enhances the adhesion of soldermask, dry film, and liquid photoresist to copper substrates. Ideally suited to eliminate the need for pumice or mechanical scrubbing, it delivers an optimized surface topography that maintains high speed signal integrity. The process enhances adhesion for fine line processing with uniform etching allowing for improved electrical performance of the layer.

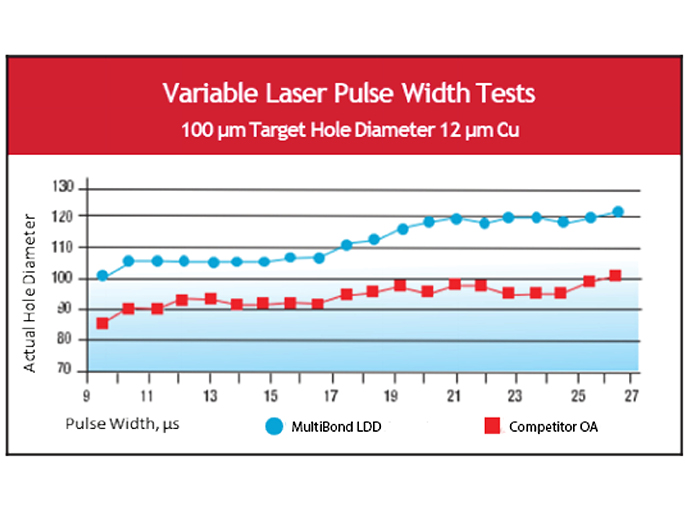

Alternative Oxide for Laser Direct Drilling

MultiBond™ 500 is an innovative low-etch alternative oxide for laser direct drilling. Due to its improved topography, color, and lower etch depth, the process enables improvements in laser direct drilling of vias through enhanced absorption of laser energy during the drilling process, while providing optimized topography for the most demanding adhesion requirements. The process provides a highly uniform dark colored alternative oxide coating for lasering. From start to finish, MultiBond 500 removes less than 1 micron of copper from the surface.