High Reliability Plating for High Aspect Ratio Through Holes

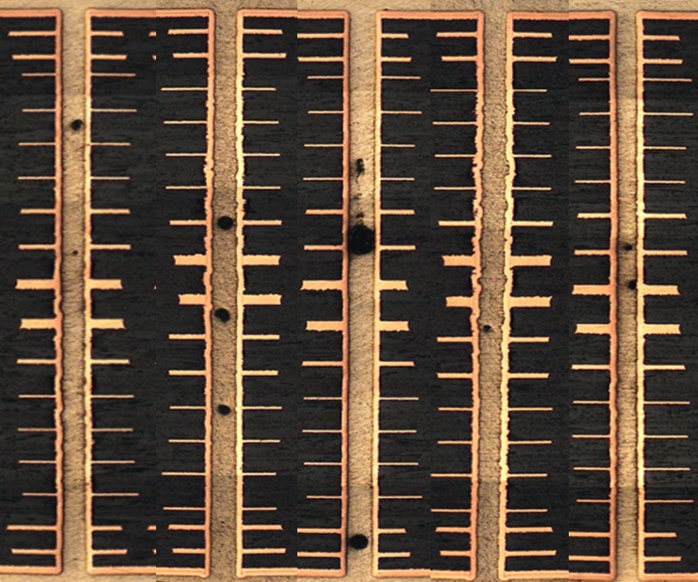

Data centers, communications systems, and high-performance computing require thick boards with dense circuitry to accommodate today’s advanced high bandwidth applications. Compared to previous generations of technologies, these electronics house boards are even thicker and have longer operating lifetimes than in previous generations. Our high-performance through hole electroplating processes enable printed circuit board (PCB) manufacturers to reliably connect the layers of thick multilayer boards with excellent microdistribution and minimal surface copper plating.

We develop copper through hole plating solutions that bring upgraded technology for a range of board sizes, so that no matter what kind of high layer multilayer board you are manufacturing, it can be built with more reliability and with less surface copper than before.

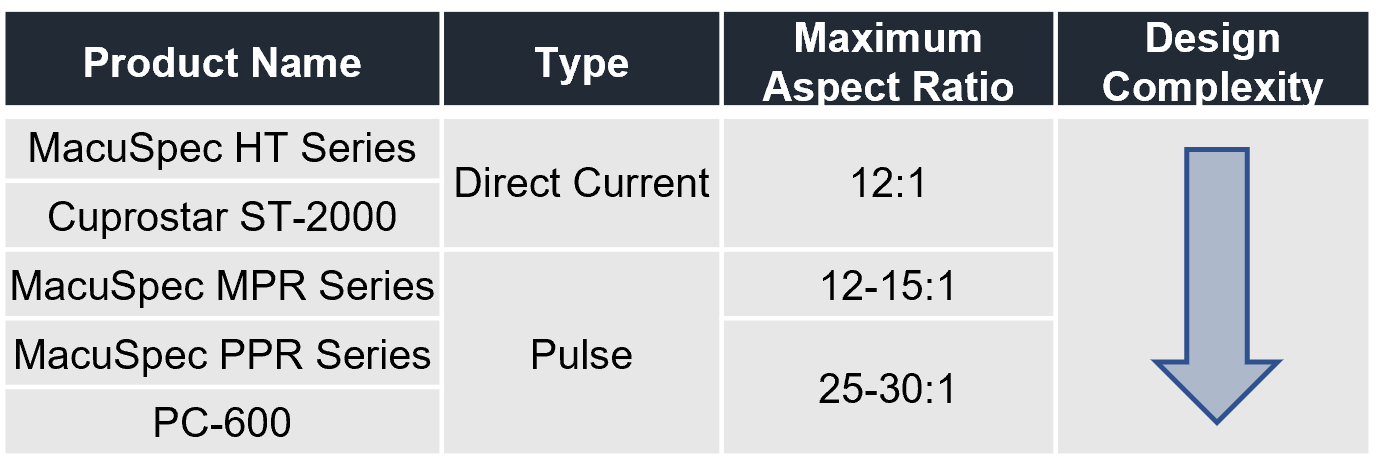

High Throw Direct Current Plating Solutions

For high layer count boards that do not have extremely high aspect ratio holes, our high throw direct current (DC) plating solutions are excellent for achieving improved operational efficiency with the reliability and performance beyond that of a standard DC plating solution. The high throwing power of these baths extends the need for customers to upgrade to pulse plating while greatly increasing the manufacturing capabilities of the site. Compared to standard direct current plating solutions, our high throw direct current technology allows excellent physical properties required to withstand harsh assembly conditions while also achieving significant savings on wasted copper that would normally be plated on the surface.

Periodic Pulse Reverse Plating Solutions

Our range of pulse plating solutions enable manufacturers to plate designs with very high layer counts and high aspect ratios. These baths provide exceptional reliability for thick, high technology boards while also allowing high process throughput due to their application of pulse rectification technology. Our offerings include a mid-range pulse plating bath that can plate boards with aspect ratios of up to 15:1 with extremely high manufacturing throughput as well as baths that can allow up to 30:1 aspect ratio with excellent performance for today’s thickest boards.

To learn more about our through hole plating processes, click here.

Contact a MacDermid Alpha Representative About High Layer Count Designs Today

We are looking to partner with manufacturers that are growing their production capabilities in the high aspect ratio or high layer count board type space. Please contact us for more information using the contact us link below.