Setting the Standard for High-Yield mSAP

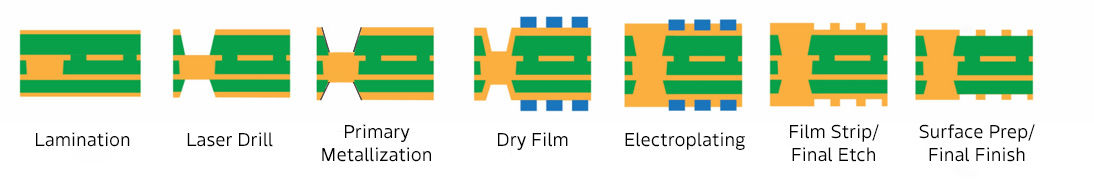

Our product selection for modified Semi-Additive Process (mSAP) for high density circuitry is increasing yields and enabling new designs. mSAP is a cost-effective process for fine line substrates which allows for a high degree of automation, high yields, and lean manufacturing. MacDermid Alpha Electronics Solutions has a portfolio which encompasses every process step including circuit formation, copper electroplating, etching, and final finishes.

As higher densities are required to encompass all of the functionality required for today’s mobile devices, IC substrates, and substrate-like printed circuit boards (PCBs), manufacturers began relying on mSAP to meet their design requirements. Reliable technologies that can deliver the yields and quality necessary for this challenging manufacturing paradigm are only offered by chemical suppliers with the technical expertise and technological capability to deliver.

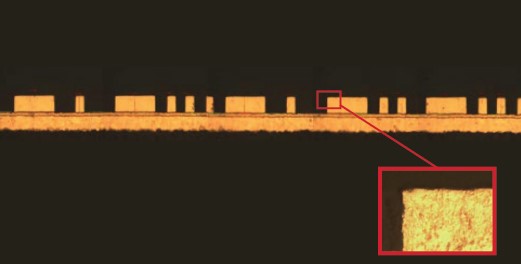

MacDermid Alpha offers a complete suite of specialty solutions for manufacturing with high density mSAP, enabling our customers to achieve results that they would otherwise be unable to with regular process chemistry. Our copper reduction technologies allow for precise tuning of copper foil thicknesses, while our innerlayer and laser drilling pretreatment processes enable high signal speeds and tight via tolerances. Our low-etch direct metallization processes allow for fewer copper interfaces and higher quality fine line resolution due to reduced etching. Our leading edge copper electroplating technologies enable fine lines and spaces with zero planarization between layers, and can even eliminate v-Pitting without the need for baking the panels after plating.

MacDermid Alpha offers a complete suite of specialty solutions for manufacturing with high density mSAP, enabling our customers to achieve results that they would otherwise be unable to with regular process chemistry. Our copper reduction technologies allow for precise tuning of copper foil thicknesses, while our innerlayer and laser drilling pretreatment processes enable high signal speeds and tight via tolerances. Our low-etch direct metallization processes allow for fewer copper interfaces and higher quality fine line resolution due to reduced etching. Our leading edge copper electroplating technologies enable fine lines and spaces with zero planarization between layers, and can even eliminate v-Pitting without the need for baking the panels after plating.

Our high resolution final etch defines traces with excellent sidewall profiles and zero undercut, and our selection of final finishes offers a wide variety of functional surfaces to meet assembly requirements. Global device original equipment manufacturers (OEMs) are using our cutting edge manufacturing processes for mSAP to power the next generation of high performance electronic devices that are being built today.

To view our mSAP sales sheet, click here.

mSAP Product Selection

| Process | Product Name |

|---|---|

|

Copper Reduction |

|

|

LDD Pretreatment |

|

|

Innerlayer Adhesion |

|

|

Primary Metallization |

|

|

Dry Film Adhesion |

|

|

Copper Via Filling / Through Hole Plating |

|

|

Dry Film Stripper |

|

|

Differential Etch |

|

|

Solder Mask Adhesion |

|

|

Final Finish |

Contact a MacDermid Alpha Representative About mSAP Today

We are looking to partner with manufacturers that are expanding their capacity to add high density layers using modified Semi-Additive Processing. Please contact us for more information using the contact us link below.