XMAPP information

XMAPP Partners

We are proud to work with the accredited XMAPP partners listed below. These XMAPP partners are automotive Tier 2 manufacturers that consistently leverage XMAPP technology to optimize design and verification costs and guarantee supply of high-performance parts in production.

For automotive OEM and Tier1 manufacturers XMAPP streamlines manufacturing partner selection, enables collaborative working and reduces supply chain risks.

Ideal for dashboards and display units with high performance characteristics.

For automotive OEM and Tier1 manufacturers XMAPP streamlines manufacturing partner selection, enables collaborative working and reduces supply chain risks.

Ideal for dashboards and display units with high performance characteristics.

XMAPP Technology

XMAPP is designed to ensure XtraForm materials and processes are implemented in the most efficient way, reducing time and cost to market and achieving agreed production quality and yield targets of automotive smart surfaces.

XMAPP technology and in-depth expertise collaborates with all levels of the supply chain, providing expertise in design for manufacture, part validation and process yield optimization as well as materials, process and equipment selection.

To learn more about XMAPP technology and support capability please contact us.

XMAPP technology and in-depth expertise collaborates with all levels of the supply chain, providing expertise in design for manufacture, part validation and process yield optimization as well as materials, process and equipment selection.

To learn more about XMAPP technology and support capability please contact us.

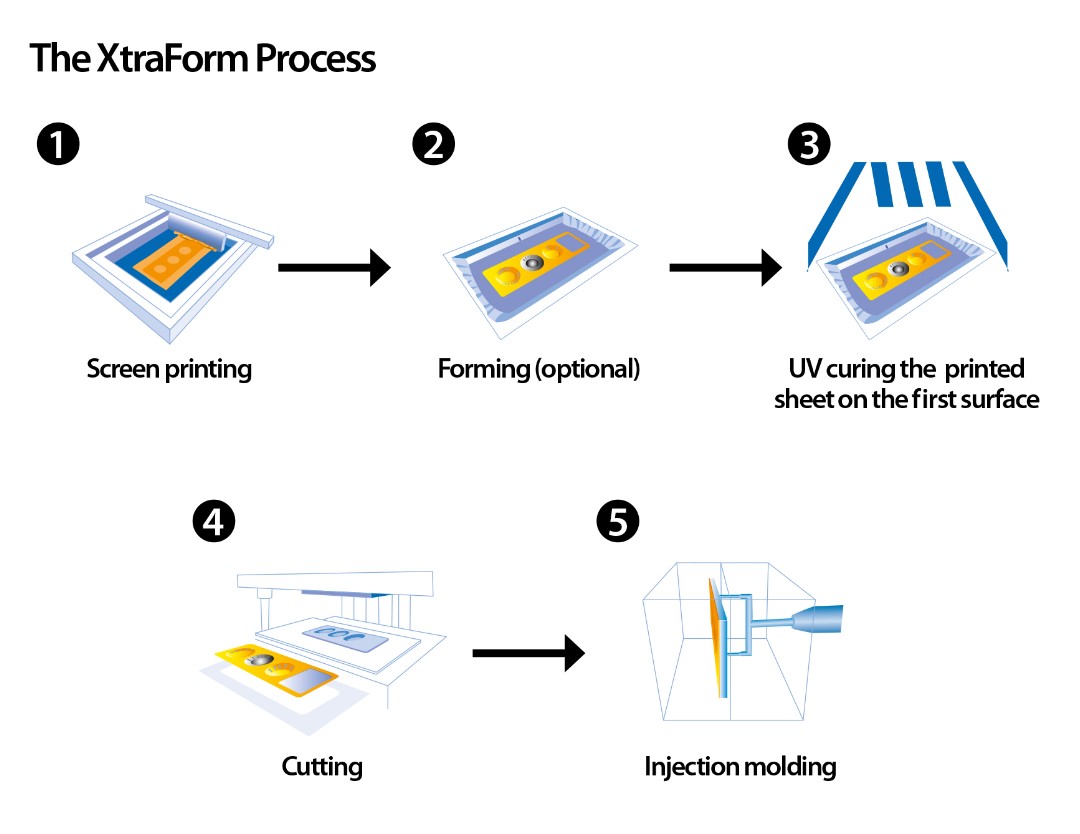

XtraForm Process

The XtraForm process is a variant of Film Insert Molding (FIM) including the addition of UV curing after the forming stage. This allows MacDermid Alpha to produce extremely formable films which are cured as a final step to produce hardcoated parts with unrivaled performance.