Product Overview

Each process step of Affinity™ ENIG 2.0 is optimized to work together to create an extremely uniform nickel-phosphorous distribution and low variation in pad-to-pad gold thickness. As a result, the entire process is highly resistant to penetrating corrosion and conforms easily to all known specifications including the stringent IPC 4552.

Product Features

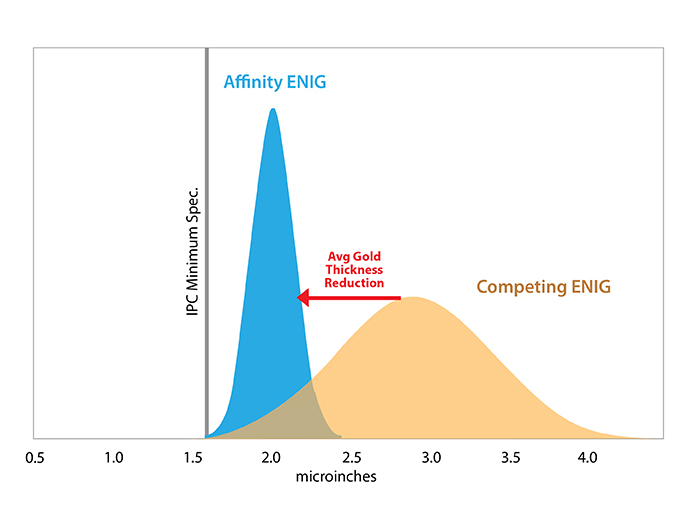

- Savings on gold costs due to tight plating window

- Dummy free at startup and during operation

- Thermally stable additives for reduced process variation.

- Minimal surface variation – every pad is the same.

Each process step of Affinity ENIG 2.0 is optimized to work together to create an extremely uniform nickel-phosphorous distribution and low variation in pad-to-pad gold thickness. As a result, the entire process is highly resistant to penetrating corrosion and conforms easily to all known specifications including the stringent IPC 4552.

Affinity 2.0 Sales Sheet (EN)

Affinity 3.0 Sales Sheet (EN)

Achieving A Successful ENIG Finished PCB Under Revision A Of IPC Technical Publication SMTAI 2017 (EN)

Cyanide Free Immersion Gold Suitable For Pcb Surface Finishing Technical Publication SMTAI 2015 (EN)

PCB Surface Finishes Technical Publication SMTNet 2015 (EN)

Quantitative Analysis of Corrosion Resistance for Electroless Ni-P Plating Technical Publication APEX 2013 (EN)

Silver & Change: A Tale of Silver, Copper, Nickel, and Gold Technical Publication PCB007 2015 (EN)

Affinity Gold 3.0 Sales Sheet (SC)

Affinity Flex Sales Sheet (SC)

Tighter Gold Window and Dummy Free Operation Equals Savings

The latest IPC specification for sufficiently defect-free ENIG processing requires that the gold thickness distribution is tightly controlled around a lower mean than previously called for. The Affinity ENIG 2.0 electroless nickel and immersion gold baths are formulated to work together to produce a process with a standard deviation in gold thickness far below that of any competing system.

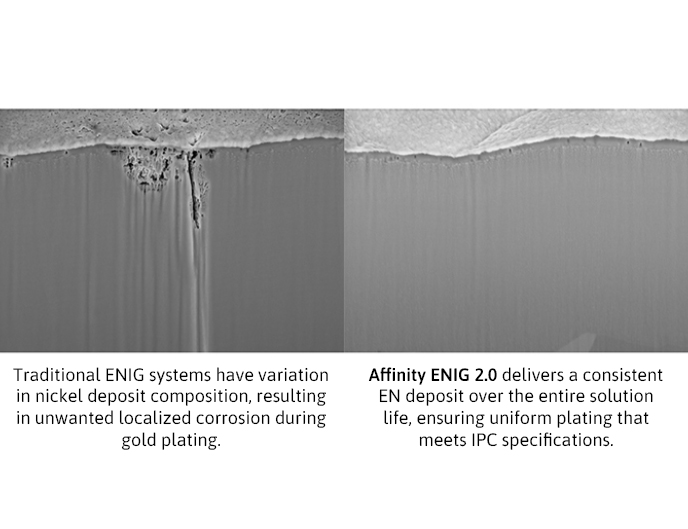

Reduction of Corrosion for Reliability

Affinity ENIG 2.0 is a highly stable, low corrosion electroless nickel / immersion gold process developed with the needs of OEMs and quality engineers in mind. The benefits of Affinity ENIG 2.0 come from its highly tightened process variation compared to competing processes. Low variation means savings due to reduced gold plating consumption.

Affinity ENIG 2.0 is the result of developments in leading ENIG technologies from our integrated companies combined with new innovations from our experienced plating staff experts.

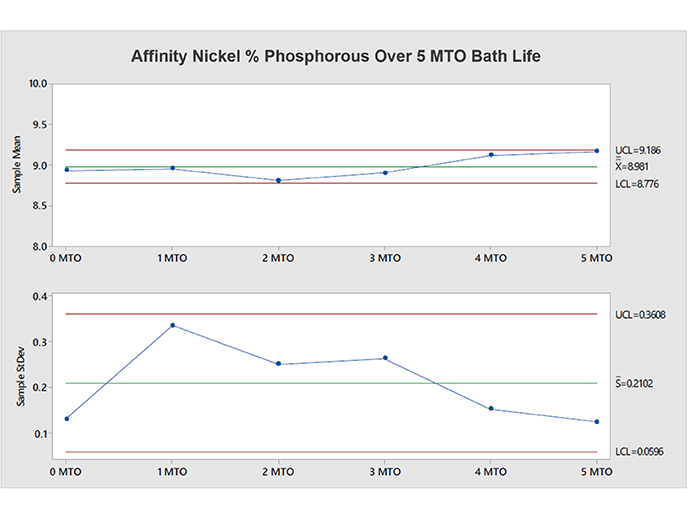

Tight Nickel-Phosphorous Percent Distribution

Consistency is everything. Affinity ENIG 2.0 comes with one of the most advanced electroless nickel baths sold for electronics manufacturing. The temperature resistant stabilizer and dummy free operation allow for savings in operating costs. The highly uniform phosphorous content prevents catastrophic failures in reliability of soldered components.