Product Overview

The ENTEK Organic Solderability Preservative (OSP) brand is the industry’s most trusted and widely used on the market today! ENTEK PLUS IC is the latest addition to the ENTEK OSP family, providing performance and yield improvement for substrate manufacturers.

ENTEK PLUS IC’s industry leading thickness capability allows unrivalled shelf life of 24 months, providing supply chain flexibility and performance risk elimination associated with other OSP’s. With proven resistance to de-flux materials, ENTEK PLUS IC OSP maintains thickness through cleaning operations, delivering reliable performance for subsequent assembly operations ensuring yield maximization.

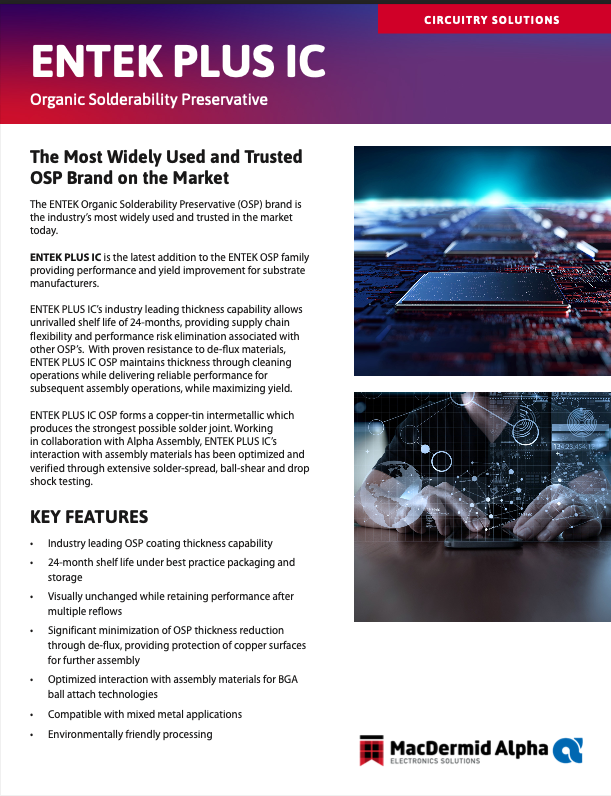

ENTEK PLUS IC OSP forms a copper-tin intermetallic producing the strongest possible solder joint. Working in collaboration with Alpha Assembly ENTEK PLUS IC’s interaction with assembly materials has been optimized and verified through extensive solder-spread, ball-shear and drop shock testing.

Product Features

- Industry leading OSP coating thickness capability.

- 24-month shelf life under best practice packaging and storage.

- Visually unchanged retaining performance after multiple N2 reflows.

- Significant minimization of OSP thickness reduction through de-flux providing protection of copper surfaces for further assembly.

- Optimized interaction with assembly materials for BGA ball attach technologies.

ENTEK PLUS IC

ENTEK PLUS IC

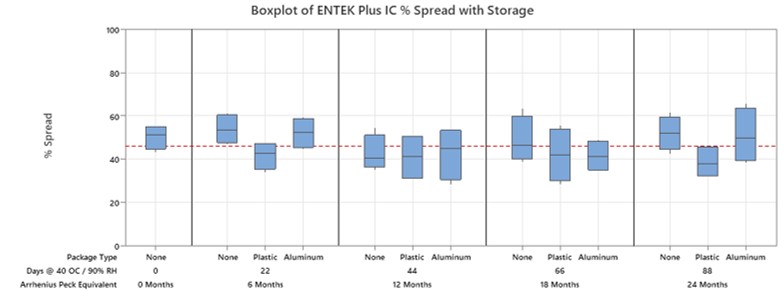

ENTEK PLUS IC OSP provides unrivalled thickness capability, providing greatly increased protection to copper surfaces on storage when compared to competitive OSP coatings.

Accelerated age tests based on the Arrhenius Peck model demonstrates that ENTEK PLUS IC exhibits no reduction in solder spread performance, providing industry leading storage times (under best practice conditions) of up to 24-months.

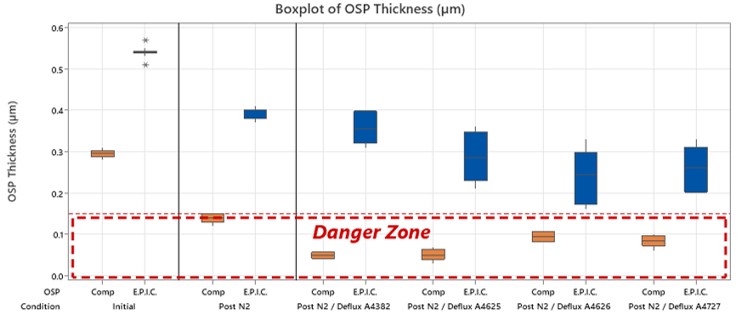

ENTEK PLUS IC OSP coatings of higher thickness allow higher OSP thickness to remain on copper surfaces after nitrogen reflow when compared to the thinner starting OSP thicknesses of competitive technology.

The combination of a thermally robust OSP molecule and the ability to maintain a higher OSP thickness through the IC substrate manufacturing process allows ENTEK PLUS IC more tolerance to deflux chemistry and any baking operations (underfill cure, etc.) during the fabrication process. This helps maximize yields at final assembly.

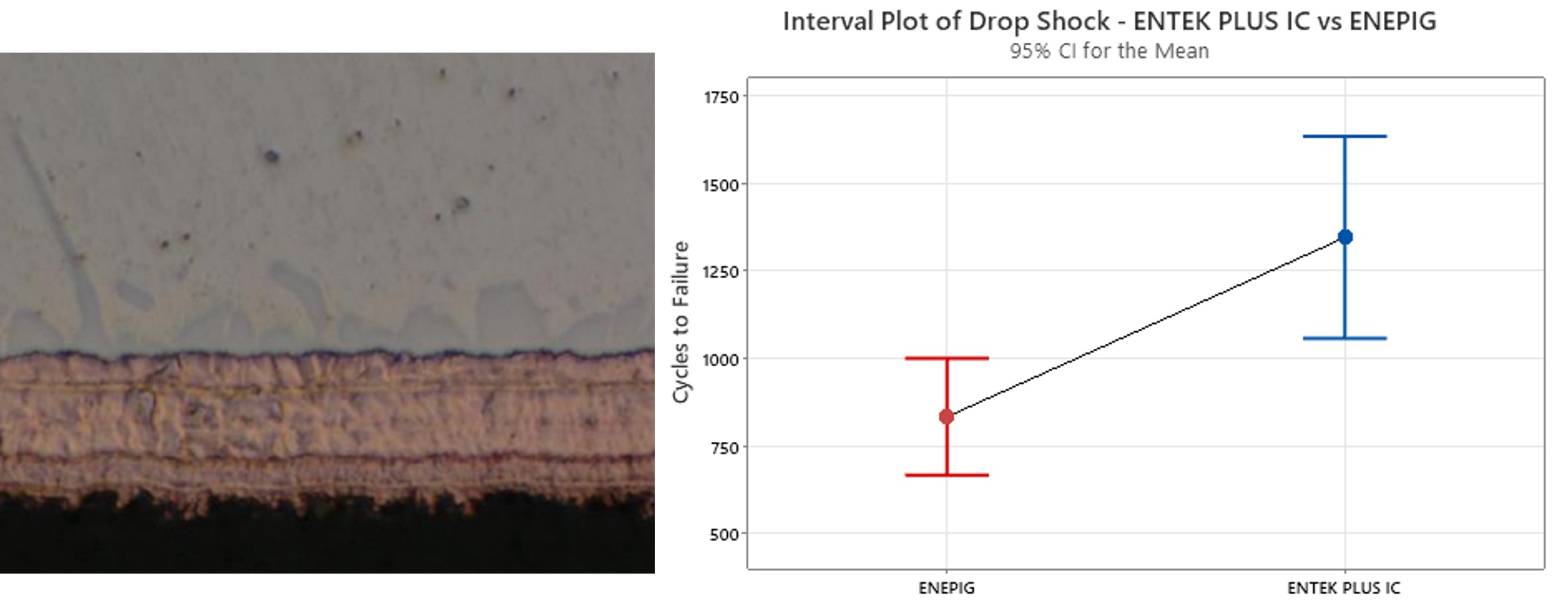

ENTEK PLUS IC Solderjoints

ENTEK PLUS IC OSP provides high reliability solderjoints.

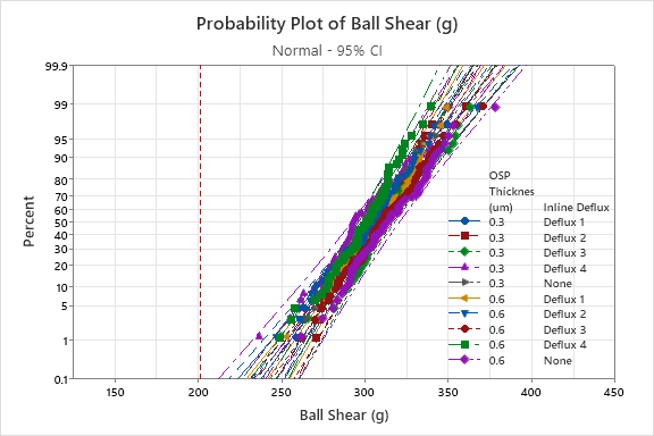

Ballshear and drop shock testing of 250 µm diameter solder spheres on 250 µm diameter BGA pads following N2 reflow and treatment with four different deflux chemistries shows highly reliable solderjoints with excellent joint strength repeatability.

ENTEK PLUS IC produces the preferred Cu-Sn intermetallic upon soldering. Extensive drop-shock testing to the IPC/JEDEC-9706 standard shows ENTEK PLUS IC produces a solder joint with the highest reliability when exposed to free fall impact.