Product Overview

Our immersion tin processes represent the pinnacle of trusted reliability for tin metal final finishes in the automotive electronics segment and beyond. Whether you are building boards for press fit technologies, backplanes, or fine pitch applications, the ORMECON® and MacStan HSR processes can deliver excellent and consistent results that can be counted on to protect board surfaces before and during assembly operations.

Product Features

- Industry leading immersion tin processes for automotive and general PCB final finishes

- Long shelf life

- Tolerates multiple lead-free assembly reflows

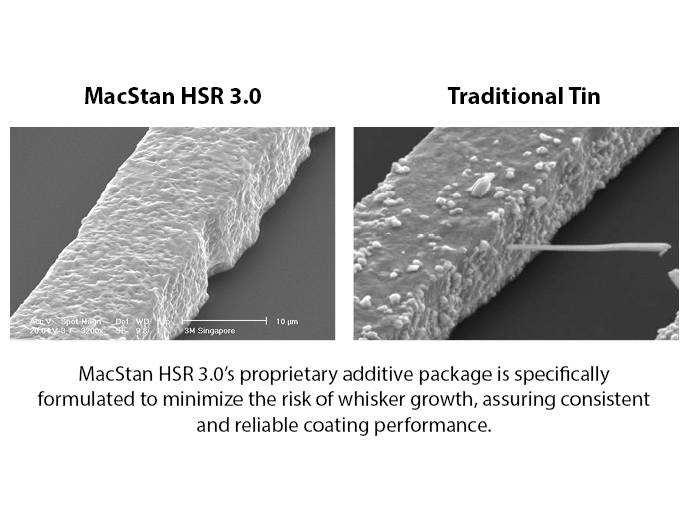

- Unique crystal structures that resist whisker formation

Organic Metal-Based Immersion Tin Processes

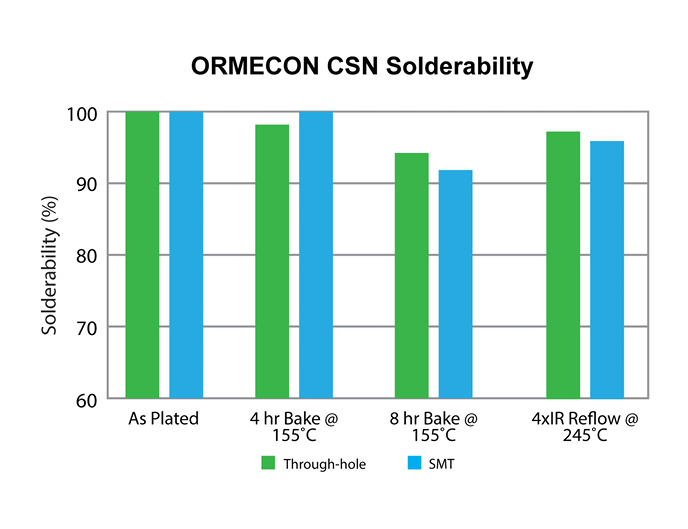

ORMECON CSN Classic is a series of extremely stable immersion tin processes that meets the requirements for all high technology markets that qualify immersion tin final finishes. Based on a patented organic metal pre-dip, the tin processes are production-proven to reduce copper-tin diffusion speed by as much as 65% and catalyze the tin deposition. As a result, exceptional solderability and appearance, even after multiple lead-free assembly reflows, is achieved.

Ideally suited for press fit technology, backplanes, and fine pitch applications, ORMECON CSN Classic processes can be operated with either MSA or sulfuric acid-based systems providing the most flexible immersion tin plating systems in the industry. The robust process window ensures stable plating quality over a long bath life. The low operating temperature of the process, ease of rework, and excellent deposit properties make ORMECON CSN Classic the immersion tin process with the best overall cost of ownership available.

The processes use an organic nanometal that is contained in the ORMECON OMP 7000 series pre-dip. ORMECON CSN Classic’s patented predip provides a mild barrier to diffusion of copper into the tin while also creating a unique low-stress grain structure which greatly reduces whisker formation. The pre-dip makes the PCB highly resistant to oxidation and copper diffusion. This pre-dip reduces tin melting risk by creating an immersion tin with low silver content in the bulk of the deposit.

MacStan HSR 3.0

MacStan HSR 3.0 is the immersion tin plating process designed specifically to inhibit whisker formation and deliver a tin deposit with an extended shelf life of up to 12 months.

MacStan HSR 3.0 is another high performance product from the leader in final finishes. It offers a chemically stable, low foaming and efficient application process that delivers excellent Pb-free solderability and an extremely planar surface. Exceptionally reliable with a high resistance to corrosion, MacStan HSR 3.0 enables effortless thickness control while maximizing bath and process stability. This ultimately results in higher yields and less overall waste. Fabricators, assemblers, and OEM’s can trust MacStan HSR 3.0 to help them meet both RoHS requirements and WEEE directives.