Product Overview

The Systek SAP copper metallization process is a high performance semi-additive primary metallization for IC substrates with multiple process improvements. The system is specifically designed as a metallization seed layer for unclad build up substrates and is composed of a complete line of process chemistry including desmear, conditioning, activation, and metallization processes. For completion of the build-up process, Systek SAP is compatible with Systek advanced 2-in-1 plating technology, allowing the filling of copper micro vias and plating of traces simultaneously. The combined process improvements of Systek SAP enable very high density circuitry with minimal substrate roughening for enhanced layer performance and reliability.

Product Features

- Complete set of process chemicals from desmear through copper

- Ionic and colloidal activator options

- Low stress electroless copper deposit for excellent reliability

- For fine line spacing down to 5/5 µm line and space

The Systek SAP copper metallization process is a high performance semi-additive primary metallization for IC substrates with multiple process improvements. The system is specifically designed as a metallization seed layer for unclad build up substrates and is composed of a complete line of process chemistry including desmear, conditioning, activation, and metallization processes.

Semi-Additive Process Technologies for IC Substrate Build-Up

The Systek SAP family of high performance build-up processes for IC substrate RDL provides multiple process flows for different materials, as well as revolutionary technology innovations in pre-treatment, conditioning, activation and copper plating steps. These processes provide the optimal metallization seed layer for build-up substrates. Process flows for fine-line, ultra fine-line, and flex materials are available for new design possibilities in manufacturing of high-density IC substrates.

Systek SAP Copper Technology

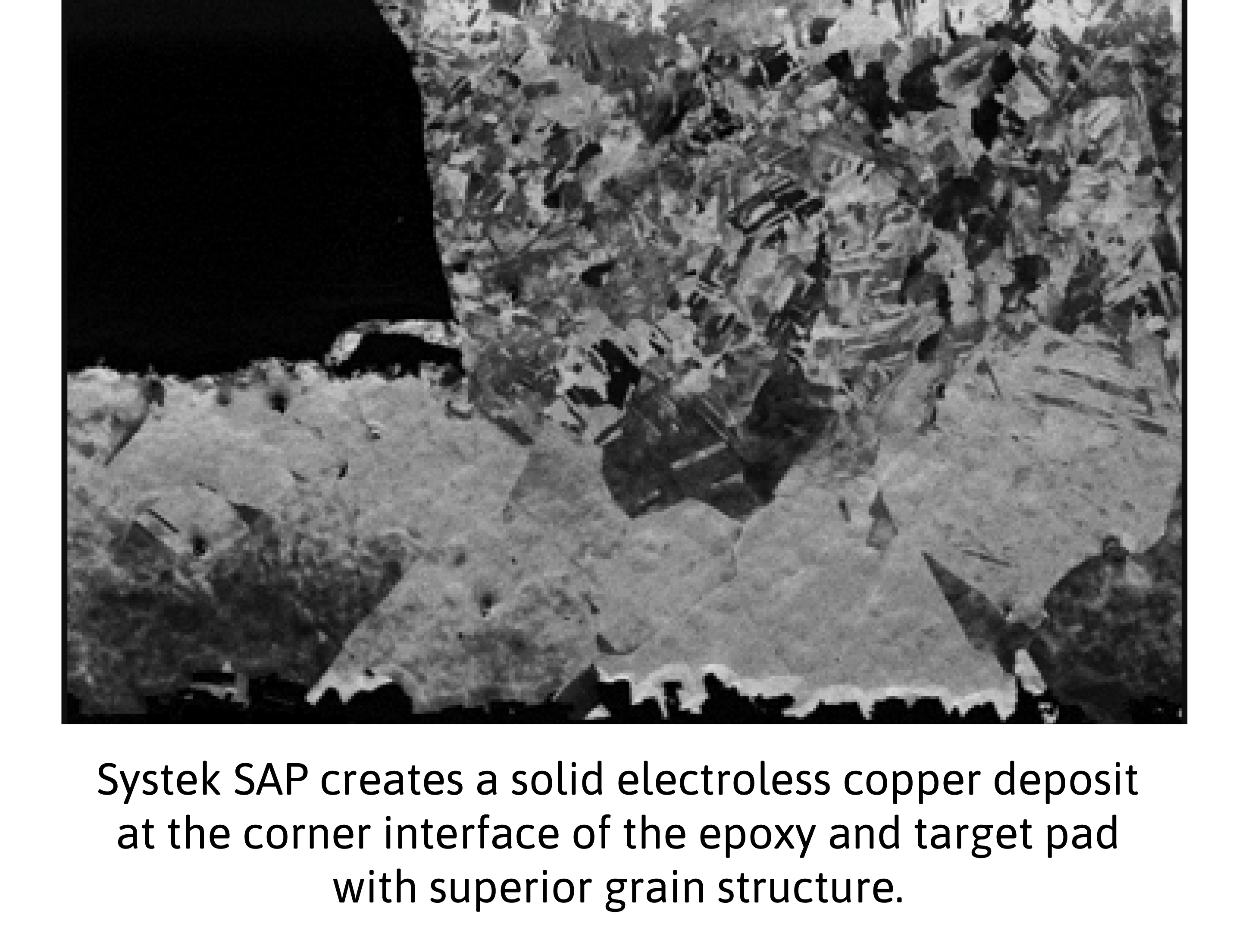

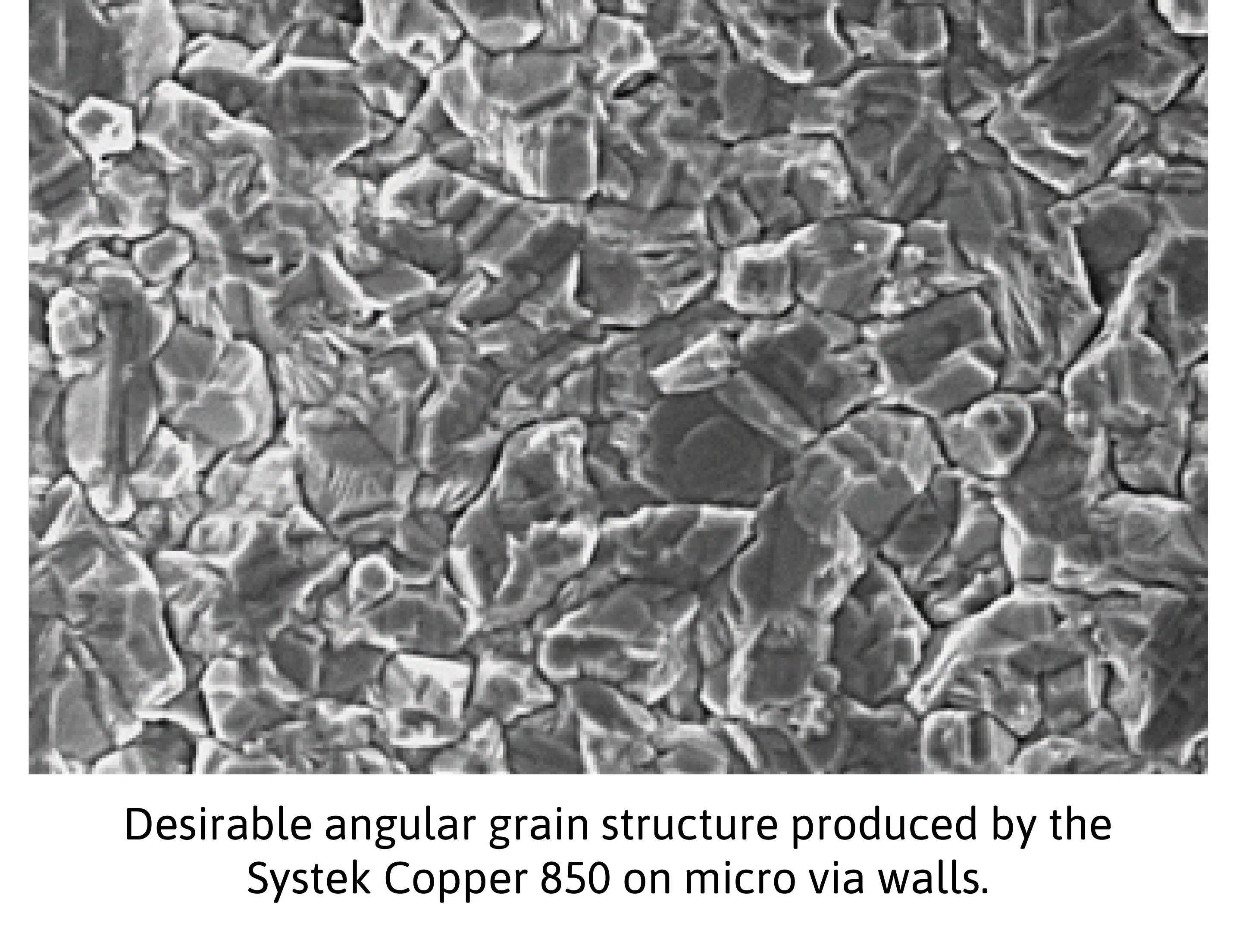

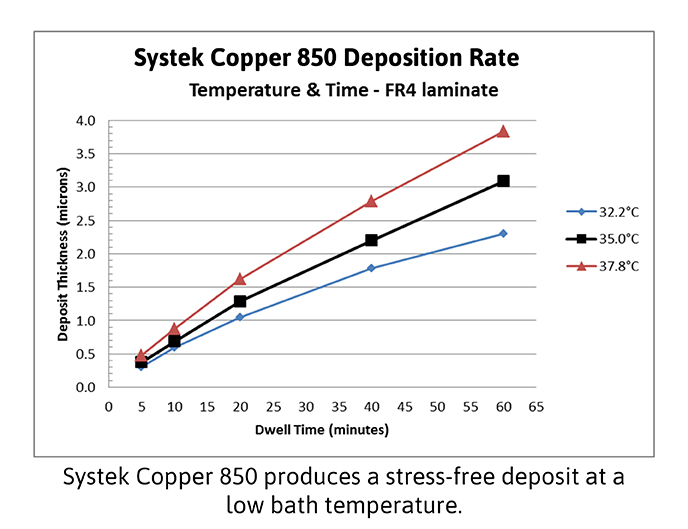

The Systek SAP Copper 850 is an electroless copper plating process that deposits electroless copper with stellar physical properties. Following desmear, conditioning, and activation of the substrate with an ionic palladium activator, the prepared micro via structures enter the final electroless copper plating stage. The activated substrate is plated with 1 micron thick copper by the Systek SAP Copper 850, which can be processed in either horizontal or vertical equipment.

Systek SAP Copper 850 is an environmentally friendly tartrate-based solution that operates at a low temperature of 25-38° Celsius. The stress-free copper deposit allows reduced roughness on the substrate surface, resulting in improved signal properties without sacrificing adhesion. While traditional electroless copper is known for its poor elongation and high internal stress properties, the electroless deposit produced by the Systek SAP Copper 850 is stress free and has 10-16 % elongation tested according to ASTM-E-345.

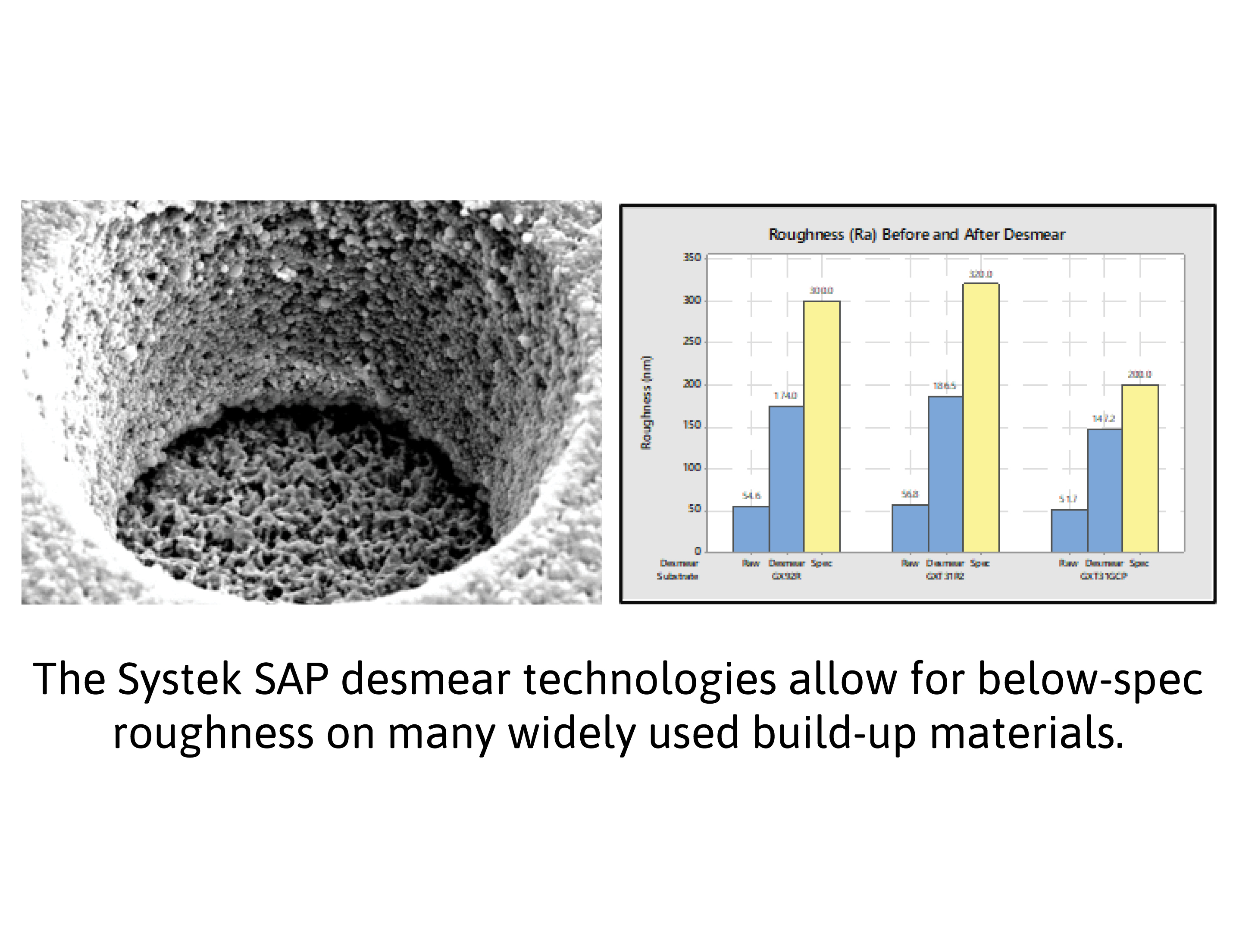

Systek SAP Desmear Technology

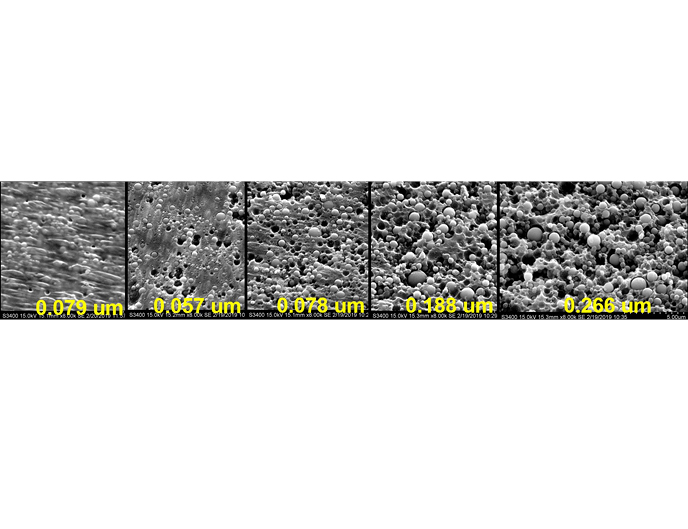

Systek SAP starts with a three step desmear process that can be calibrated to optimally prepare multiple substrate materials, depending on the fabricator’s choice of design. First, a permanganate etch removes laser debris from via walls and target pads. Next, a neutralizer reduces the permanganate residues from the surface. Finally, a glass etch promotes uniform palladium adsorption on glass build-up material. The result is a perfect balance of minimal roughness and consistently clean via side walls and copper target pads for maximum adhesion.

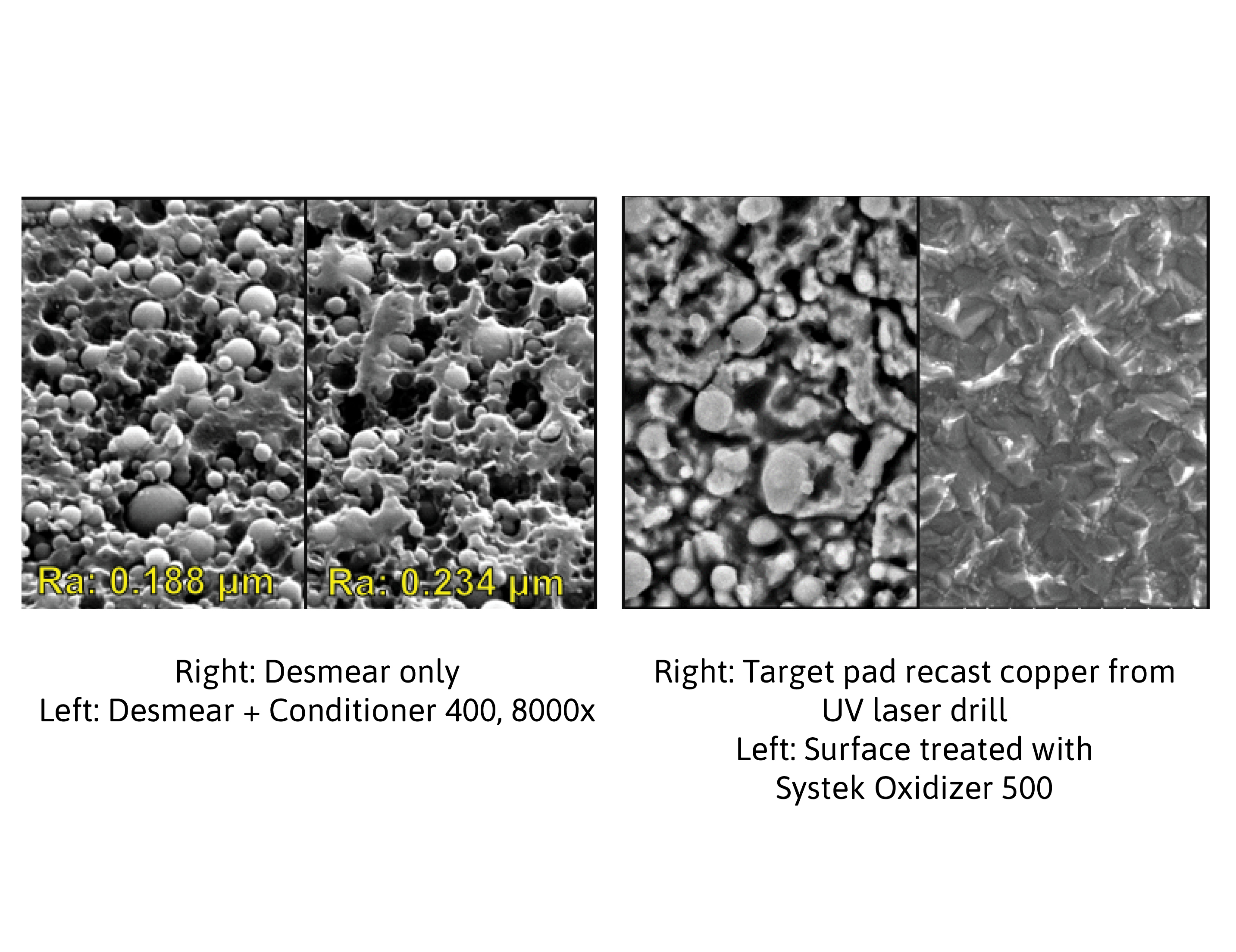

Systek SAP Conditioner Technology

The purpose of the conditioner process is to impart substantivity, ensuring that the substrate adsorbs the palladium catalyst which is the electroless copper initiation site. The Systek SAP conditioner process is a three step system that includes a chemical bond enhancing pre-conditioner, a cationic conditioner, and a target pad activating micro etching oxidizer. In concert, these three processes allow unparalleled process activation quality and electroless copper initiation in hard-to-reach and hard-to-clean areas of the SAP build-up layer.

Systek Desmear

Systek Desmear provides a well-prepared surface for superior adhesion between the base material and electroless Cu seed layer with minimum surface roughness. It includes glass etch or frost to maximize the bonding strength with smooth glass beads. Systek Desmear provides a clean via target pad and is laser residue free. The permanganate etch maximizes adhesion with minimum surface roughness and the new sulfuric acid free glass etch technology provides uniform glass frost and increased peel strength.