Product Overview

Our line of desmear chemistries provide the optimal surface to maximize successful application of either direct metallization or electroless copper.

Product Features

- Multiple options for hole conditioning for a wide array of board materials

- High performance permanganate system available in liquid and powder forms

- Selection of neutralizers including glass etches to maximize performance of subsequent activation

Our line of desmear chemistries provide the optimal surface to maximize successful application of either direct metallization or electroless copper.

M-Series Desmear Sales Sheet (EN)

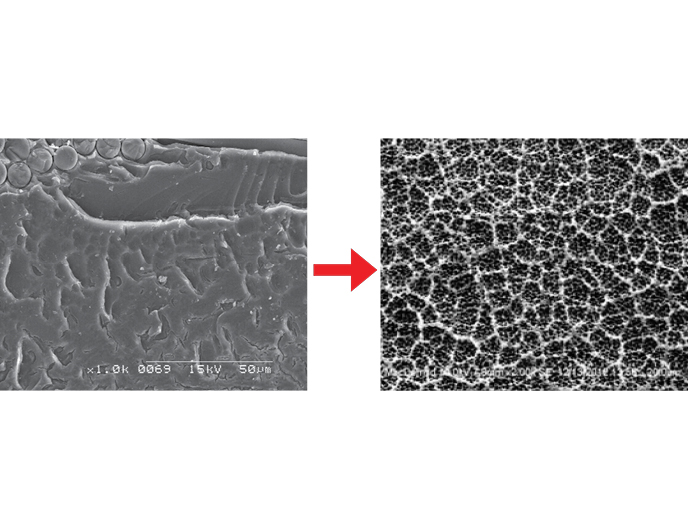

Hole Conditioning

Depending on the type of board material, a solvent is utilized to swell the surface. Whether using our M-Treat BIO for its rapid, uniform smear removal or the M-Treat AQ for its ability to increase hole wall topography, our hole conditioning processes are finely tuned to meet the requirements of the PCB manufacturer.

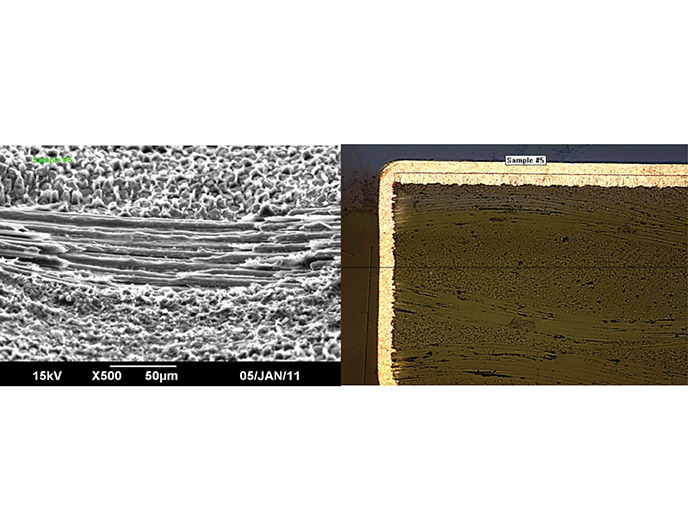

Oxidation and Neutralization

Through oxidation of the drill residue, M-Permanganate L/P removes the resin smear while promoting wetting on the surface below. Our neutralizer processes then remove remaining oxidizer residue from the surface, preparing it for activation in electroless copper or direct metallization. M-Neutralizer is a standard reducer solution, while M-Neutraetch is an etching reducer. M-Glass Etch is a glass frost that is used separately or in tandem with a standard neutralizer to provide extra surface topography if needed.