MacDermid Alpha Electronics Solutions Launches Shadow® Plus: Advanced Direct Metallization Technology for Cutting-Edge, High-Density Applications

MacDermid Alpha Electronics Solutions Launches Shadow® Plus: Advanced Direct Metallization Technology for Cutting-Edge, High-Density Applications

(Waterbury, CT USA) – February 6, 2025 - MacDermid Alpha Electronics Solutions, a leading supplier of integrated materials and chemistries to the electronics industry, is delighted to introduce Shadow® Plus. This ultra-stable, graphite-based direct metallization technology addresses the automotive and electronics industries’ need for increased functionality and reliability of electronic devices with higher density, and advanced circuit designs.

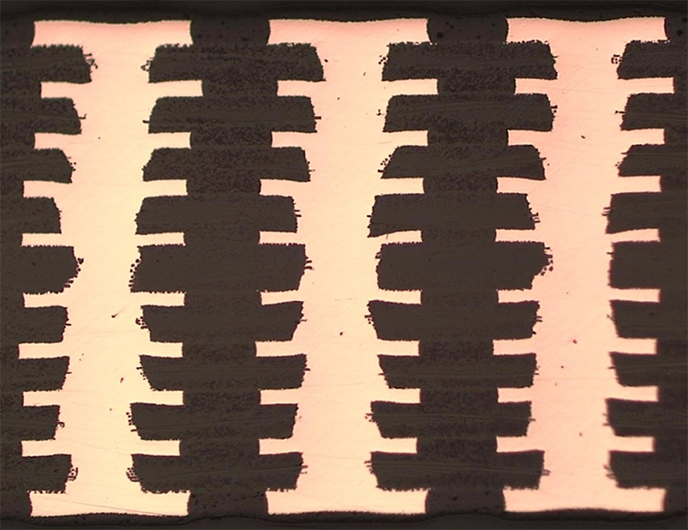

Shadow Plus, a recognized advanced alternative to electroless copper, helps PCB fabricators drive innovation, enhance operational efficiency, and reduce environmental impact. Leveraging patented wet etch technology, Shadow Plus enables the creation of finer line and space designs while ensuring reliable interconnects, meeting the demands of today’s high-density, advanced circuit designs.

With its unmatched chemical stability, Shadow Plus minimizes sludge generation, optimizes equipment utilization, and reduces the overall processing time. The environmental benefits are further amplified through significant reductions in water consumption and energy use, as well as the elimination of formaldehyde - offering fabricators a more sustainable solution than traditional electroless copper and other direct metallization processes. This breakthrough technology is a testament to MacDermid Alpha’s commitment to providing industry-leading solutions that support both operational performance and sustainability goals. "As technology evolves, the demand for higher functionality and increased board density with reliable performance has become critical," says Carmichael Gugliotti, Product Manager – Primary Metallization at MacDermid Alpha. "PCB manufacturers need solutions that offer both high performance and sustainability. Shadow Plus delivers on these needs, providing proven reliability for even the most demanding designs, while offering significant environmental benefits compared to electroless copper processes.”

In production we see that Shadow Plus provides greater process efficiencies over other direct metallization processes through:

- Increased chemical stability, reduced sludge, and increased equipment utilization.

- Faster propagation leads to increased process yields and throughput.

- Reduced number of dryers leading to savings in power consumption.

With over 30 years of expertise and more than 600 direct metallization lines in use globally, MacDermid Alpha continues to lead the way in high-performance, environmentally responsible PCB fabrication solutions.

Discover how our latest direct metallization technology can benefit your production line. Please reach out to a member of the team or contact us.