Product Overview

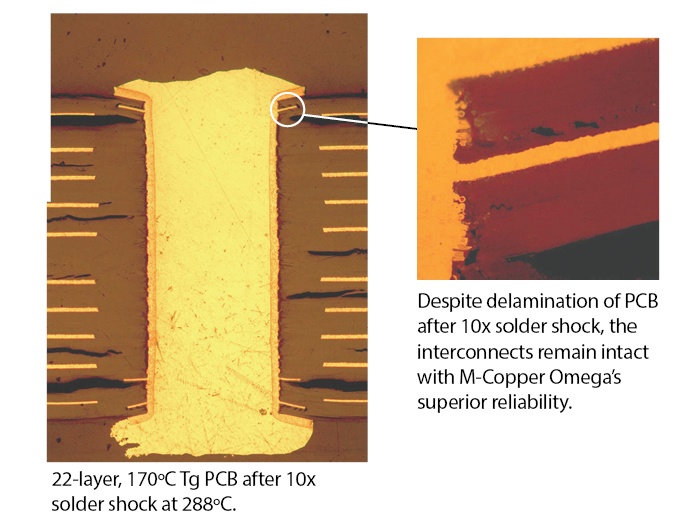

Our highly reliable electroless copper technologies for plated through hole metallization have grown with electronics manufacturing over decades. Our M-Copper Omega® is the reliability standard for vertical electroless copper plating. Our Via Dep™ 4550 is a stress-free electroless copper for both horizontal and vertical configurations that is excellent for flexible printed circuitry.

Product Features

- Excellent first pass yields

- Wide selection of technologies for various board designs

- Formulations available for flexible PCB, high aspect ratio boards, and HDI

- Global applications support

The MacDermid Enthone brand of electroless copper processes have long been a market leader in high-reliability and performance for demanding PCB applications. Our electroless coppers are ideally suited for performance critical to the success of multilayer boards. We offer a wide variety of options for any substrate type and end application to meet your design goals.

Microvia Reliability Brochure (EN)

Via Dep 4550 Sales Sheet (EN)

Adhesion To Very Smooth Substrates Utilizing An Optimized Semi-Additive Process Technical Publication IMPACT 2014 (EN)

Optimized Semi-Additive Process for Polyimide As Dielectric In Build Up Packages Technical Publication APEX 2015 (EN)

Process Improve Strategies for Weak MicroVia Interface Technical Publication APEX 2021 (EN)

mSAP Sales Sheet (EN)

M-System

M-System integrated desmear–electroless copper was developed using design for six sigma techniques to provide a proven primary metallization system to fit the needs of the industry. The first stage of the process is a chemical desmear process designed for today’s variety of special resin systems. The process can be tailored to run in vertical or horizontal equipment. The second stage is our advanced electroless copper processes with options from low build to high build thicknesses.

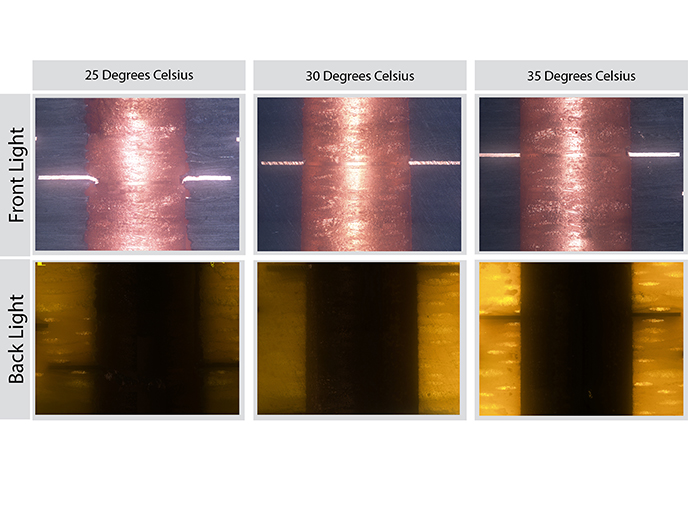

The core of the process is our M-Condition line of conditioners selected for various material including FR-4 epoxies, polyimide, flex or high frequency, low loss materials, and our M-Activate system. Together with our patented M-Accelerate system, we can offer superior back light coverage and strong interconnects that consistently survive the stresses of thermal expansion and movement in reflow and assembly. M-Copper processes can be chosen for the specific thickness range desired given the dwell time and whether processing is vertical or horizontal.

M-Copper Omega

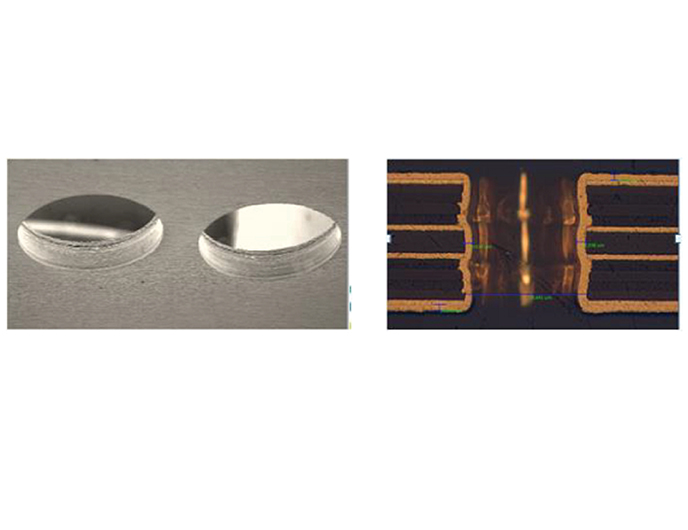

The M-Copper Omega is a high dep metallization process combines a unique, patented activation sequence with a statistically designed electroless copper bath. The patented activation sequence utilizes nontraditional conditioning and acceleration steps to enhance glass coverage. This enhanced coverage yields superior post pattern plate backlight performance. The statistically designed electroless copper bath will produce the highest reliability on microvias and high aspect ratio holes.

M-Copper EF

M-Copper EF is the only electroless copper system on the market that is sold by an international plating supplier which can outperform local suppliers at a competitive price in both vertical and horizontal equipment. M-Copper EF is specifically formulated from decades of experience with electroless copper plating and modern innovations to allow for a revolution in quality and service in a segment of the PCB industry that rarely sees new offerings.

M-Copper EF

Your OEM customers will feel more confident knowing that their products were assembled with a process backed by a world-class organization. M-Copper EF-H is formulated for horizontal lines. With M-Copper EF you can rest assured that you are using only the best electroless copper metallization available. Don’t fall into the trap of compromising quality for cost, with M-Copper EF, you can have it all.

Via Dep 4550

The Via Dep 4550 electroless copper system is the industries choice primary metallization for difficult-to-plate substrates. The 4550 process offers superior adhesion on inert surfaces and difficult structural designs while maintaining structural integrity. The zero-stress blister free deposit for SAP, mSAP and Flex applications assures that your metallization needs on complicated hybrid devices can be met with ease. Via Dep 4550 H is formulated for horizontal lines.