Revolutionizing Profitability through Advanced Direct Metallization Technology

Written By

Jim Watkowski

Vice President of Innovation

Circuitry Solutions

MacDermid Alpha Electronics Solutions

Want to speak to an expert? Connect with us here:

Revolutionizing Profitability through Advanced Direct Metallization Technology

Leveraging change as a catalyst to enhance profitability in the printed circuit board (PCB) fabrication industry is both a strategic imperative and a promising opportunity. In an era of rapid technological evolution and shifting market dynamics, embracing change is not just a choice; it is a necessity. By continually adapting to new manufacturing technologies, materials, and design methodologies, PCB fabrication companies not only stay competitive but also drive increased profitability.

Innovations such as advanced precision direct metallization, the adoption of greener materials, and the growing market demand for High-Density Interconnect (HDI) solutions are reshaping the PCB fabrication industry.

Innovations such as advanced precision direct metallization, the adoption of greener materials, and the growing market demand for High-Density Interconnect (HDI) solutions are reshaping the PCB fabrication industry.

As the industry evolves to meet customer expectations—such as faster turnaround times, smaller form factors, and increased functionality—PCB fabricators and their OEM customers need to adapt to these demands. This includes addressing the growing demand for HDI, which can help them position themselves as agile industry leaders.

By embracing these transformations, they can meet evolving market needs, remain competitive, and realize the rewards of heightened profitability. In the dynamic PCB fabrication sector, embracing change is not just a strategy; it is the essential key to sustainable success and growth.

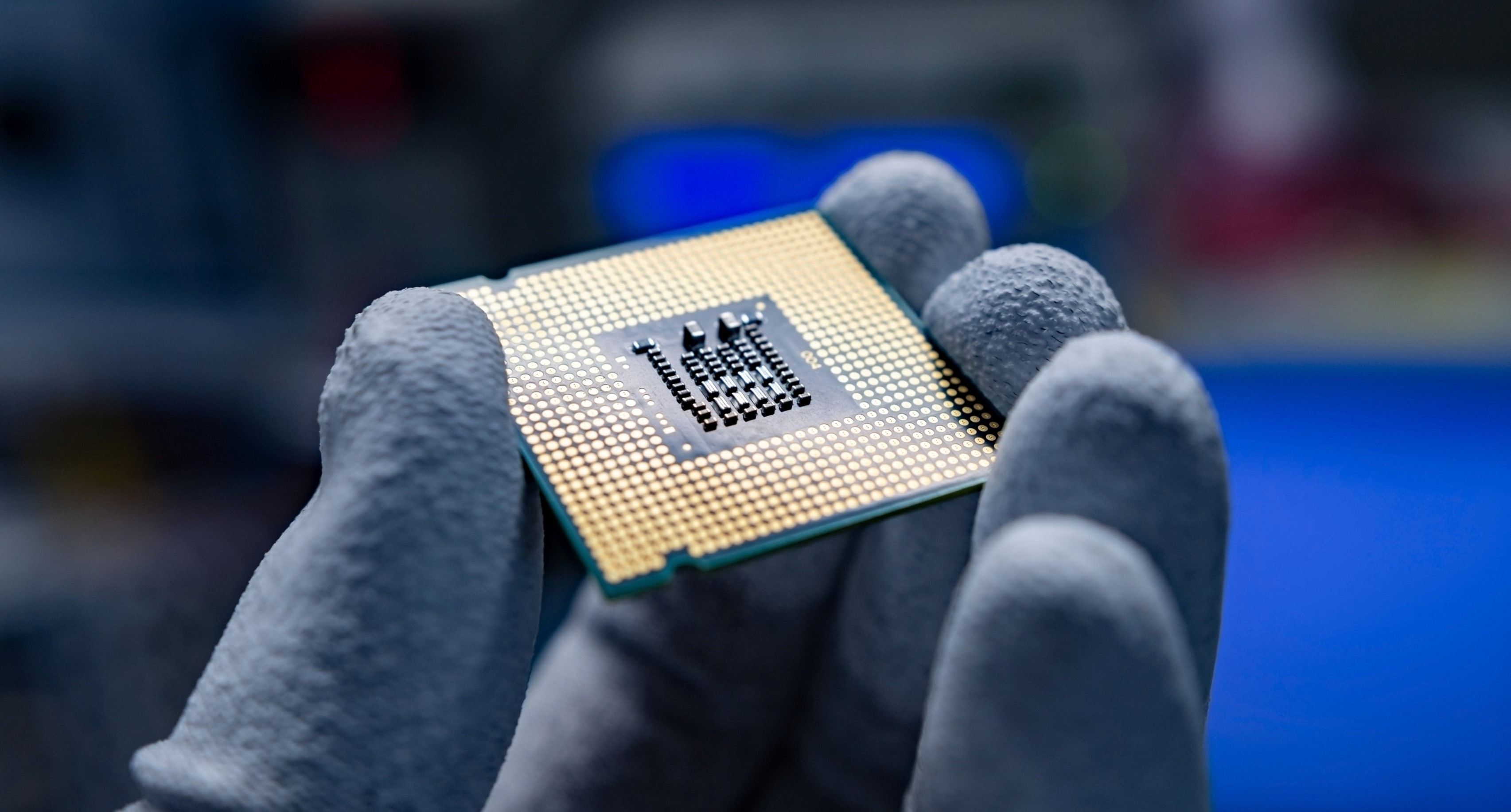

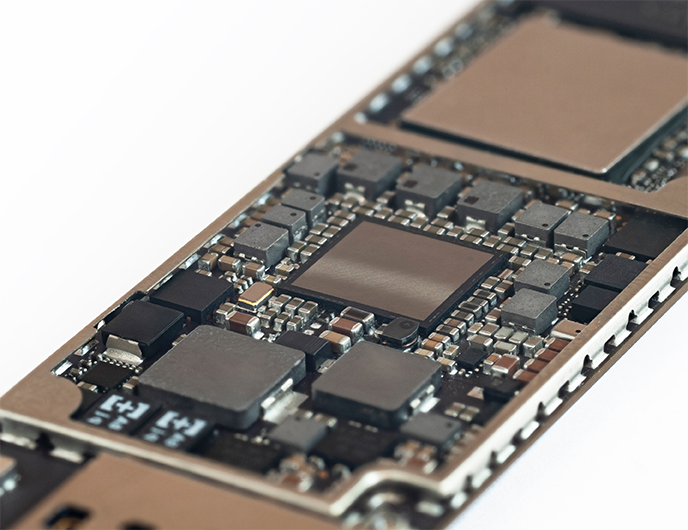

The ever-evolving world of electronics is shaped by a myriad of captivating trends that redefine our relationship with technology, both at work and in our daily lives. One prominent trend is the relentless pursuit of miniaturization, resulting in electronic components shrinking in size to create sleeker, more portable devices with higher functionality. Simultaneously, drive for speed accelerates electronics to new heights, enabling lightning-fast input/output (I/O) data processing and improved performance across interconnected devices and applications.

These trends reflect the dynamic nature of the electronics industry. They promise a future filled with groundbreaking innovations extending beyond corporate profitability and improving the quality of life. As someone deeply involved in this industry, collaborating with experts from various sectors, I am constantly amazed by the rapid pace of change and the multitude of emerging opportunities. We, in the electronics industry, are no strangers to disruptive forces, continuously striving to achieve smaller, faster, lighter, and more functional innovations, poised for transformative advancements in the years to come.

Supporting Industry with Innovative Chemistries and Processes

During a recent customer visit, I engaged in discussions concerning the profitability challenges within the PCB fabrication industry. As margins continue to erode, we find ourselves navigating a commoditized market with increasingly slender profit margins. However, what struck me during these conversations was the wealth of untapped opportunities. These opportunities range from implementing systematic changes to embracing smaller incremental adjustments. Nonetheless, one prevailing theme emerges: revitalizing profitability hinges on adopting a fresh perspective that drives innovations in our fabrication processes and materials. Profitability is a deliberate choice that demands proactive, forward-thinking measures, especially as we navigate a landscape where innovation and change serve as catalysts for renewed prosperity.

In my capacity as Vice President of Innovation at MacDermid Alpha, I am fortunate to collaborate and engage with experts from various facets of this industry, including designers, manufacturers, suppliers, OEMs, and more. What strikes me most during discussions with industry experts is the remarkable pace of change and the array of opportunities developing on numerous fronts.

From the development of advanced chemistries and metallization processes to the evolution of sustainable materials, our industry is poised for significant transformations in the years ahead, and we are here to support these changes.

Partnering for Progress

In an industry moving toward miniaturization, where electronic components are continually reduced into smaller packages with increasing numbers of pins, PCB fabrication materials and processes must evolve to meet the challenges of higher interconnection densities.

Here's how MacDermid Alpha can provide invaluable assistance:

Drawing on over four decades of expertise in direct metallization, MacDermid Alpha is playing a pivotal role in facilitating the transition of production lines to their cutting-edge direct metallization technologies, elevating their capabilities to produce higher-density PCB designs and meet the demands of next-generation devices.

Our suite includes carbon, graphite, and conductive polymer direct metallization options, which serve as alternatives to conventional electroless copper plating. These alternatives incorporate advancements in chemistry specifically designed to support the latest HDI technologies and fabrication processes, such as mSAP. They enable the production of significantly finer signal lines with tighter spacing. Simultaneously, our chemistry portfolio coupled with the proper equipment reduces costs, cycle times, water usage, chemical usage, energy consumption and carbon footprint.

MacDermid Alpha’s advanced direct metallization technologies, which exceed the reliability of the incumbent process, are suitable for fabricating both simple and complex circuit boards, from flexible and rigid-flex circuit boards to novel hybrid board construction - all in alignment with our commitment to developing materials and process chemistry that contribute to a safer and more sustainable planet.

Our state-of-the-art direct metallization technologies enable PCB fabricators to meet the industry’s evolving demands, with reliable, cost-effective solutions they need to succeed.

Interested in transitioning to direct metallization?

Talk to our experts here and we'll help you take the first step