Product Overview

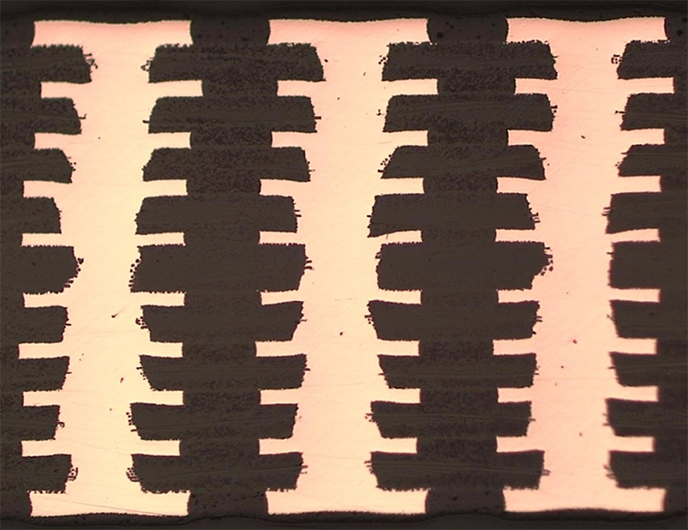

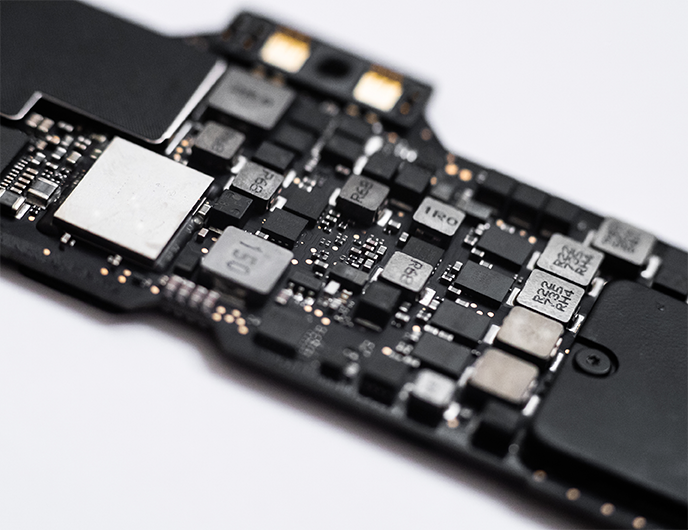

Today, over 600 of these direct metallization lines are in production around the world. These technologies offer customers lower water usage, less waste generation, smaller equipment footprints, and palladium-free activation for significant operations savings. At the forefront, Shadow Plus, our low etch direct metallization technology, is enabling the latest generation of mobile designs with fine line width and spacing through mSAP on Ultra-thin copper foil.

Product Features

- Suite of carbon, graphite, and conductive polymer alternatives to electroless copper

- Reduced power, water, and chemical consumption results in an eco-friendly process for fabricators and OEMs alike

- Less-hazardous chemistries and processes that eliminate palladium and formaldehyde

- Direct copper-to-copper bonding creates fewer metal interfaces

Blackhole LE and Eclipse LE, our low etch direct metallization technologies, are enabling the latest generation of mobile designs with fine line width and spacing through mSAP on 3-micron copper foil.

Blackhole Sales Sheet (EN)

Blackhole LE Sales Sheet (EN)

Eclipse Sales Sheet (EN)

Eclipse LE Sales Sheet (EN)

ENVISION HDI Sales Sheet (EN)

Microvia Reliability Brochure (EN)

Shadow Sales Sheet (EN)

Direct Metallization System for Flexible Printed Circuit Board Technical Publication SMTAI 2015 (EN)

Green Technology for the Plated Through Hole Process Technical Publication IEEE 2013 (EN)

Integrated Metallization System for High Density Interconnects and Modified Semi-Additive Processing Technical Publication HKPCA 2012 (EN)

Process Improve Strategies for Weak Microvia Interface Technical Publication APEX 2021 (EN)

The Co-Evolution of Carbon-Based Direct Metallization Alongside HDI Technology Technical Publication PCB007 2020 (SC)

The Co-Evolution of Carbon-Based Direct Metallization Alongside HDI Technology Technical Publication PCB007 2020 (EN)

The Total Environmental Solution for Any-Layer HDI Production Technical Publication IPC APEX 2014 (EN)

Use of Carbon Nanoparticles for the Flexible Circuits Industry Technical Publication SMTA 2013 (EN)

mSAP Sales Sheet (EN)

Shadow®

Graphite-Based Advanced Direct Metallization

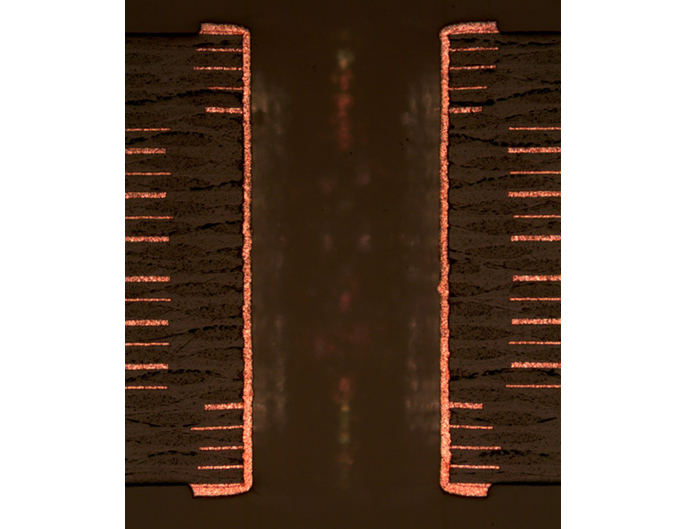

Shadow is an eco-friendly graphite based direct metallization process that makes through holes and blind vias extraordinarily conductive for copper electroplating. Shadow’s exceptional coating ability is well recognized in use on Flexible and Rigidflex, PTFE and exotic materials like LCP and hydrocarbons. Shadow is an ideal choice for today’s advanced materials and HDI / mSAP designs.

With 35+ years of technology expertise, over 300 lines, and more than 1 billion boards produced, electronics fabricators all over the world trust Shadow for their primary metallization needs.

For more information on Shadow, click here.

Blackhole®

The Lowest Cost Through Hole Metallization Process Available

Trusted by over 250 of the world’s leading manufacturers, MacDermid Alpha's Blackhole is the choice of fabricators worldwide that prefer a low cost, environmentally friendly direct metallization alternative to electroless copper. Suitable for both simple and complex circuit boards, carbon-based Blackhole is a nanoscale electrostatic coating that satisfies every need for reliability and versatility.

Blackhole is an automated, horizontal process whose unique technology enables users to reduce cycle time, decrease overall water consumption, eliminate the use of formaldehyde, and generate less waste than electroless copper plating.

Chemical consumption, waste production, engineering support, and process yield contribute to PCB fabrication cost. Blackhole provides a value-in-use which drops right to your bottom-line, minimizing costs associated with installation, operation, and final product yield.

Low etch options are available upon request.

Eclipse™

Mission-Critical PTH Reliability

Eclipse is engineered specifically for fabricators and OEMs that require consistently high performance, reliability and durability. Simpler to use and considerably more cost-efficient than electroless copper, Eclipse provides high tech capabilities and RoHS-compliance all in one.

Carbon-based Eclipse is capable of initiating 20:1 aspect ratio and higher through holes. Boards using Eclipse achieve over 500 IST cycles, and the process enables manufacturers to decrease chemical usage and water consumption by 90%. Eco-friendly Eclipse reduces process steps by 50% and eliminates 100% of chelated metals. Utilizing an automated horizontal process, Eclipse delivers unmatched coverage and connectivity for even the most challenging designs and is supported by our renowned hands-on global technical service.

Low etch options are available upon request.

ENVISION®

High Performance and Production Capacity, Environmentally Friendly

The ENVISION polymer-based system is unlike any other direct metallization process on the market today. It delivers more board capacity with substantially improved performance.

The significant cost savings rendered from the replacement of electroless copper with ENVISION are comprised of lower material, labor, equipment, and utility costs.

With ENVISION, fabricators no longer need to choose between high performance, cost reduction, and an environmentally friendlier process. They only need to choose ENVISION.