Eliminating Hotspots On Printed Circuit Boards

Authored By

Not All Thermal Interface Materials (TIMs) Are Equal

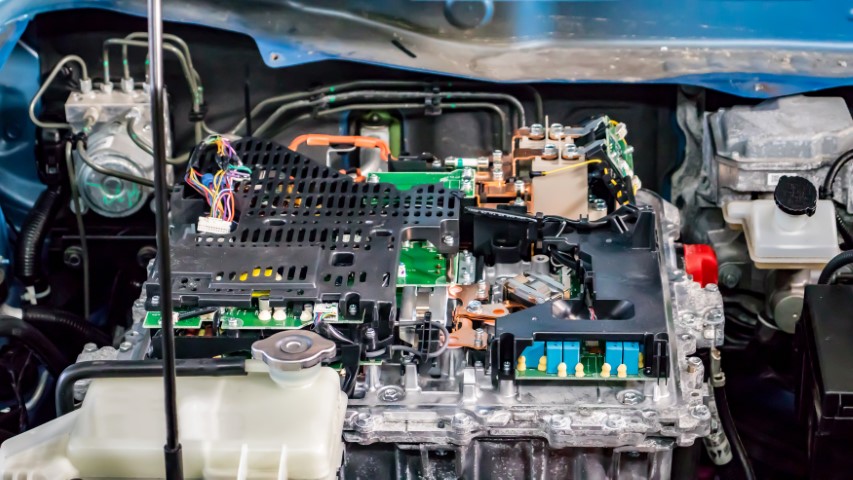

A supplier of PCB boards recently experienced these hotspots on PCB assemblies for on-board chargers. Naturally they applied a TIM (TIMs are products that conduct heat between two or more solid mating surfaces) to fill the air gaps and dissipate the heat, between the PCB and cooling channels in their on-board charger.

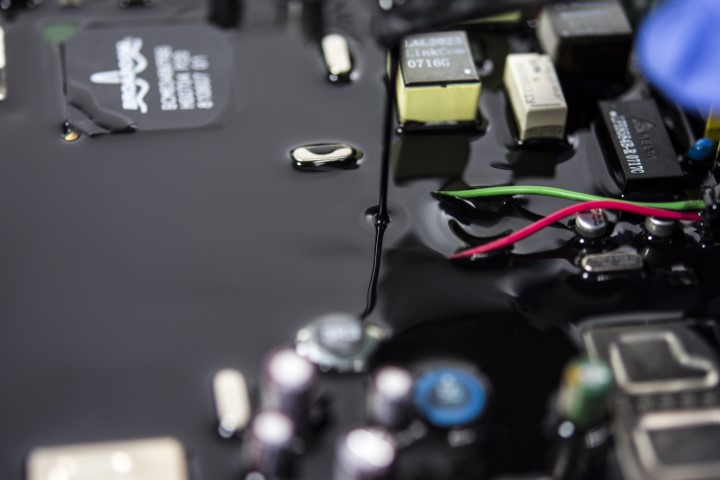

They applied a material with a thermal conductivity in the region of 4-6 W/m.K., but the issue remained. So, they consulted the experts at MacDermid Alpha, who identified that product had too high viscosity for this particular on-board charger assembly; essentially the material could not flow into the critical areas, leaving air pockets remaining after filling. Air is a poor conductor of heat, approx. 0.025 W/m.K, thus these remaining air pockets reduced the efficiency of heat transfer.

Solving Hotspot Issues For On-Board Charger Assemblies

The MacDermid Alpha polymer experts recommended a thermally conductive potting resin with lower viscosity and better flow properties (than the previous TIM). This resin provided excellent flow even in small (~0.5mm) spacings, with a good mixture of support and flexibility. When tested, it proved to fill even the smallest gaps in the unit.

Furthermore, the PCB designer required high dielectric strength, excellent protection against automotive fluids and vibration, while also offering flexibility for fragile components during thermal shock. The Electrolube polyurethane resin has a dielectric strength of 18 kV/mm and is recommended in applications where excellent thermal cycling, thermal shock and automotive fluid resistance is required. Being approved to UL94 V-0 it is also flame retardant.

Electrolube Polyurethane Resin A Success For Tier 1 Automotive Supplier

MacDermid Alpha worked with the manufacturer to achieve the most efficient production process. They recommended gently heating the material and potting the unit at a slight angle to further improve flow and flush out all air pockets. When tested, the resin flowed well through the customer’s unit, and they achieved the heat dissipation that was required. The Electrolube resin was subsequently approved for the application after demonstrating effective heat transfer between certain hot components, such as inductors and capacitors, and the liquid cooling channels within their aluminum metal casing.

Bethan Massey, Global Product Manager for Potting and Encapsulation Resins at MacDermid Alpha Electronics Solutions, summarized, “Despite the resin having a lower thermal conductivity of 0.78 W/m.K compared to the original specification, the low viscosity proved to be highly successful at eliminating any air gaps in the system, dramatically reducing the thermal resistance.

Our automotive customer was very pleased with the solution that we offered them, and we proved that our problem-solving capabilities and commitment to providing innovative and reliable solutions, secures our position as the leading provider of electro-chemical products to the automotive industry.”

MacDermid Alpha Electronics Solutions, a prominent division of Element Solutions Inc, holds a distinguished position as a global leader in the field of fully integrated materials; helping to deliver enhanced performance, reliability, and sustainability to electronic manufacturers worldwide.

Their expertise is segmented into three divisions – Circuitry Solutions, Film & Smart Surface Solutions, and Semiconductor & Assembly Solutions (SAS). The SAS division specializes in delivering cutting-edge solutions for semiconductors and assembly processes, driving innovation and reliability in these critical sectors.

With a legacy spanning over a century of innovation, MacDermid Alpha has garnered the trust of manufacturers spanning more than 50 countries.

Setting MacDermid Alpha Electronics Solutions apart is its unique ability to promptly deliver high-quality solutions and provide technical services that comprehensively cover the entire electronics supply chain. They are actively shaping industries such as automotive, consumer electronics, mobile devices, telecom, data storage, and infrastructure.

Interested in transitioning to our EV-based products in India?

Let's connect and I will help you take the first step.

Sharan Aiyappa

Automotive Industry Director - India

[email protected]