SiC, the next generation Wide Band Gap (WBG) semiconductor material is the ideal material for high temperature power electronics (for automotive and space applications).

SiC hardness and higher modulus, however, make die attach application very stressful. ALPHA Argomax family of sintered products formulated with proprietary silver particles without any organic resin form a pure sintered silver joint with high temperature stability that matches the high temperature properties of SiC. Finally ALPHA Argomax's unique lower modulus sintered microstructure helps relieve the mechanical stress associated with SiC.

ALPHA Argomax is the die attach material of choice for EV traction power module all over world.

Solution for SiC Die Attach - High reliability pure silver sintered attach enabled by ALPHA Argomax

ALPHA Argomax is enabled by proprietary nanoparticles. The materials are formulated without any resins and have been shown to withstand continuous operating temperatures (as high as 250C)

Pressure induced sintering freezes the nanostructure of the particles that forms a lower modulus die attach layer (ideal for SiC die attach).

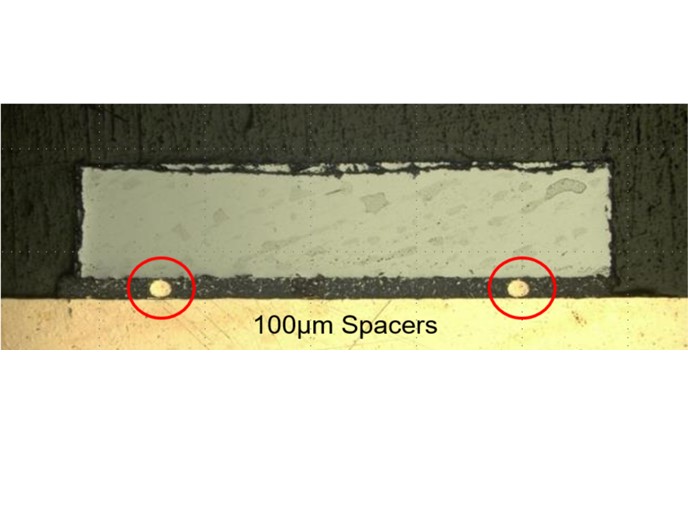

Argomax nanoparticles also enable film format. Film provides in-built bond line and tilt control without the printing and drying steps.

Products for SiC Die Attach

| PRODUCT TYPE | PRODUCT NAME | COMPATIBLE SURFACE FINISH | PRODUCT APPLICATION METHOD | END APPLICATION |

|---|---|---|---|---|

| Sinter Paste | ALPHA Argomax 2010C | Ag, Au | Die Attach, Die Top Attach | |

| Sinter Paste | ALPHA Argomax 2040 | Ag, Au | Print, Dot Dispense | Die Attach, Die Top Attach |

| Sinter Paste | ALPHA Argomax 5022 | Cu | Die Attach, Die Top Attach | |

| Sinter Film | ALPHA Argomax 8020 | Ag, Au | Die Transfer Film | Die Attach, Die Top Attach, Spacer Attach |

| Sinter Film | ALPHA Argomax 8021 | Ag, Au with special surface requirements | Die Transfer Film | Die Attach, Die Top Attach, Spacer Attach |