As IGBT dies get thinner (for lower RdSON), die attach with paste is becoming challening.

Dog-ear formed during printing can damage the thin die. This requires printing areas larger than die foot print (lower packaging density and higher cost). During the drying step, the paste can creep up along the die edges and contaminate the die top (causing issues during wire bonding / clip lamination). Finally any particles on the dried paste can damage the die during pressure sintering.

ALPHA Argomax die attach film is the ideal choice for thin die attach (<70um). No printing and drying is needed and the film is tacked on to the die with the die transfer step. The die attach film matches the size of the die (no fillet or excess die attach area) and provides built-in bond line and tilt control without die top contamination.

Thin Die Attach - with ALPHA Argomax Films

ALPHA Argomax films are enabled by proprietary nanoparticles. With film format, printing and drying steps are not needed and the format comes with in-built bond line and tilt control.

Alpha Argomax film can also be supplied in AccuLam(R) format p in which the film comes pre-scored to match the die size. This enables faster and robust transfer process at lower pressures with almost zero waste - making it an ideal format for large and thin IGBT dies.

Products for SiC Die Attach

| PRODUCT TYPE | PRODUCT NAME | COMPATIBLE SURFACE FINISH | PRODUCT APPLICATION METHOD | END APPLICATION |

|---|---|---|---|---|

| Sinter Paste | ALPHA Argomax 2010C | Ag, Au | Die Attach, Die Top Attach | |

| Sinter Paste | ALPHA Argomax 5022 | Cu | Die Attach, Die Top Attach | |

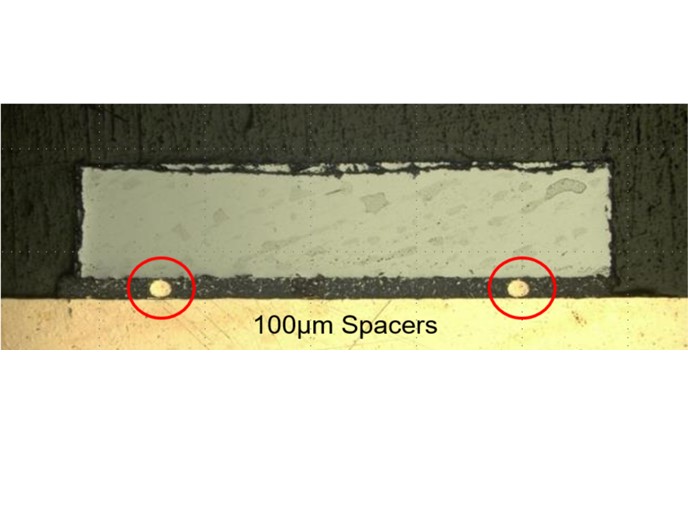

| Sinter Film | ALPHA Argomax 8020 | Ag, Au | Die Transfer Film | Die Attach, Die Top Attach, Spacer Attach |

| Sinter Film | ALPHA Argomax 8021 | Ag, Au with special surface requirements | Die Transfer Film | Die Attach, Die Top Attach, Spacer Attach |