Enhancing Safety and Performance of Small EV Motors With Thermally Conductive Potting Compounds

India’s EV Revolution Rides on Two Wheelers

India, the second-largest market for two-wheeled electric vehicles (EVs), saw a 40% increase in sales in 2023. This rapid growth is driven by government policies, promoting a rapid transition to EVs to combat air pollution. As demand grows, many manufacturers are actively working to improve performance by enhancing power, speed, range, safety, and reliability, positioning themselves to capitalize on this growing market.

Heat Challenges for Small EV Motors

Electric motors generate heat that must be effectively managed to ensure safety, efficiency, and optimal performance. In the small EV market, motors have traditionally been engineered to withstand moderately high operating temperatures ranging from 60oC to 105oC. This temperature range is considered safe and efficient for Class-A motors. However, as consumers demand increased power and speed from their small EVs, operating temperatures can rise to 150oC, and beyond, where safety and performance issues are more critical.

Heat can spread quickly through a motor, endangering heat-sensitive motor control components and potentially causing stator temperatures to exceed critical levels. Overheating beyond a critical saturation point, where the magnetic field in the core reaches its maximum capacity, increases the risk of short circuits, potentially leading to premature failure. Consequently, effective thermal management solutions are essential to prevent overheating, ensure safety, and maintain long-term reliable performance.

Beyond Basic Cooling

Larger EV motors employ active heat dissipation strategies, incorporating liquid- or air-cooling systems into their designs. However, these strategies are unsuitable for small EV motors, like those in e-bikes and scooters, where minimizing weight is a top priority.

Motors for small EVs have traditionally relied on passive cooling strategies, primarily by integrating heatsink features into the motor’s outer casing to increase its surface area and thereby enhance convective heat transfer to the surrounding air. Varnish, typically applied to the copper coil windings, provides mechanical and electrical insulation, protecting coils against contamination and electrical shorts. However, varnish does not contribute to heat management.

Next-generation e-bikes and scooters are being designed for higher power and voltages, requiring them to withstand Class-F (155oC) or Class-H (180oC) operating conditions. As a result, manufacturers are seeking improved passive thermal management solutions.

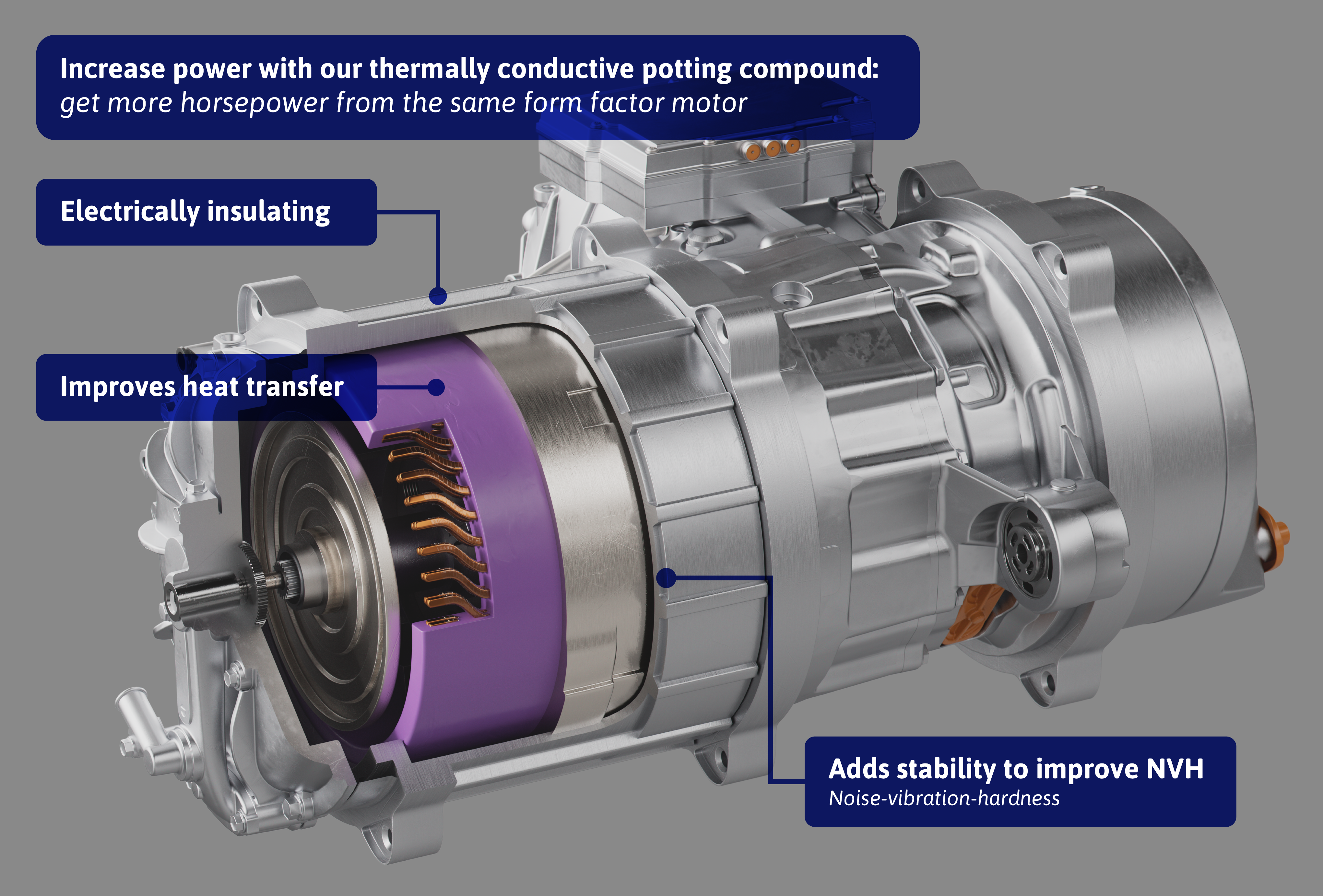

The Cool Solution – Encapsulating with Thermally Conductive Potting Compounds

Thermally conductive potting compounds, long used in other sectors of the electronics industry, are being adapted for small EV motor assembly. Available in silicone-based and epoxy-based formulations, these potting compounds are dispensed into the motor’s stator assembly where it flows around the copper windings to fill the stator compartment. Once cured, the resin hardens, effectively replacing air around the stator coil with thermally conductive material. This potting technique can reduce stator temperatures by 30oC to 50oC, depending on the formulation, and can improve mechanical stability by providing structural support and vibration dampening.

By incorporating thermally conductive potting compounds into the assembly process, small EV motor manufacturers achieve significant safety and performance benefits. This technique is increasingly being adopted to prevent overheating and enhance long-term reliability, safety, and performance.

Picking the Perfect Material

Selecting the right material is crucial for achieving optimal thermal performance. Heat dissipation is highly dependent on the thermal conductivity of the resin, but there is a trade-off between thermal conductivity and viscosity. A resin with higher thermal conductivity (TC > 3 W/mK) will have more conductive filler in its formulation, which increases its viscosity and makes the resin harder to flow. The ideal balance is achieved with a high enough TC and viscosity. However, it is important to realize that even a low TC resin (1 W/mK) is much better than no resin since the TC of air is only about 0.02 W/mK.

Silicone-based thermally conductive resin, with TC of about 3 W/mK, was the first potting compound to be used in EV motors to achieve stator encapsulation. Silicone, a soft resin with low viscosity, easily flows into most stator assemblies. However, silicone doesn’t provide much benefit in terms of mechanical stability and tends to expand significantly with rising temperatures. For these reasons, many manufacturers prefer a more rigid material like epoxy-based potting compounds.

These (epoxy-based) potting compounds are more rigid than silicones. They also expand less when heated. Thermally conductive epoxy potting compounds, with TCs ranging from 1 W/mK to 3 W/mK, are formulated with smaller filler particles to enhance flow, but they require warming to sufficiently reduce viscosity. A vacuum is often applied during application, to assist with air bubble removal. The higher rigidity of epoxy potting compounds also requires matching their coefficient of thermal expansion (CTE) with that of copper in the stator windings to prevent resin cracking during thermal cycling.

Many EV motor manufacturers prefer epoxies for mechanical stability. However, both epoxy-based and silicon-based encapsulants can effectively reduce stator temperatures. The choice depends on finding the right balance between thermal performance, mechanical support, and viscosity for the specific application.

The animation shown above provides an illustration of the technology as it moves heat from one area to another by using the compound.

Key Insights for Unlocking EV Motor Power and Performance

The following section outlines the benefits of using potting compounds and optimizing both material selection and their application:

Performance Benefits:

- For every 10oC reduction in stator temperature, motor lifespan doubles. Thus, a 30oC to 50oC decrease achieved through potting with thermally conductive resin, significantly enhances motor longevity.

- Encapsulating windings and filling the stator housing with thermally conductive resin improves power density. Data shows this approach can yield 15% to 30% more torque and horsepower from the same-sized motor.

- The benefits of potting compounds, in terms of safety, performance, and reliability outweigh any disadvantage of slightly increased weight.

- Thermal cameras confirm that potting compounds enhance thermal stability throughout the motor by reducing hot spots. Hot spots, often caused by overloading or loose electrical connections, are early indicators of potential damage or impending failure.

Material Selection:

- Potting with compounds that have moderately low thermal conductivity (1 W/mK to 1.5 W/mK) is significantly better than no encapsulation, as it replaces air, which has a thermal conductivity of only 0.02 W/mK.

- There is a sweet spot for conductive filler particle size. Particles should be small enough to flow easily between windings yet large enough to ensure good contact for effective heat transfer.

- Longer cure potting compounds allow more time for optimal filling. Once filled, the curing process can be accelerated with heat.

Processing:

- When dispensing epoxy-based thermally conductive potting compounds, it’s best to warm both resin and housing to 60oC to 70oC. This improves flow and adhesion, minimizes voids, and reduces the risk of thermal shock.

- Strong adhesion to the motor casing is crucial for optimal heat transfer. This can be accomplished by curing at elevated temperatures, with good results seen between 85oC to 125oC for 1 to 2 hours.

- Encapsulating under a vacuum is recommended for epoxy-based formulations to ensure a complete fill without air bubbles or voids.

Conclusion

At MacDermid Alpha, we understand that incorporating a thermally conductive resin into an EV motor is a significant design decision. However, with proven results demonstrating substantial improvements in safety, performance, and long-term reliability, this approach is a straightforward way to meet the higher power, speed, and longevity requirements of next-generation small EVs.

As material experts, we are here to help you leverage these benefits. We collaborate closely with our clients on design and process specifications, while assisting with the selection of the right materials for their applications. We enjoy partnering with manufacturers and are honored to contribute to their success.