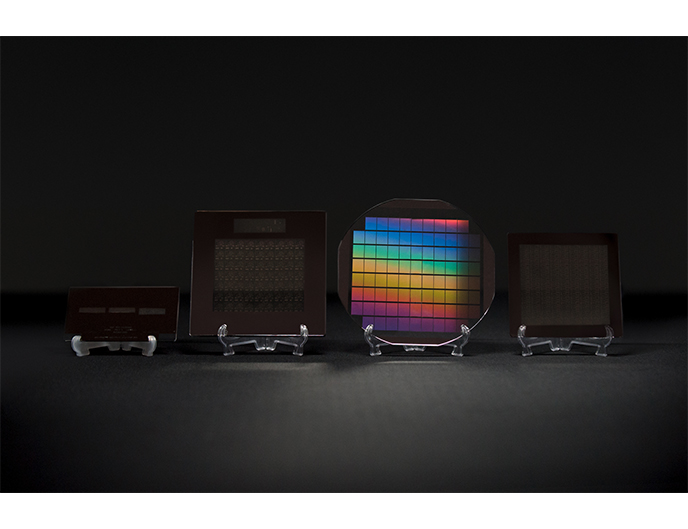

Standard Binary Photomasks

When our customers use hard contact, close-proximity printing or projection aligners to transfer the design to their substrates, little or no attrition of the photomask occurs. These systems typically use broadband or near-UV light (300-450nm) to expose the wafer or substrates. While still at the same scale factor (1X) as the final device, higher pattern fidelity and tighter specifications can be met using photomasks made directly by our lithography tools. 1X Masters can be made on either soda-lime (SL) glass or fused silica (QZ) substrates.

Solution Features

-

Range of material types, sizes and resists available

-

Support of typical specifications include Critical Dimension (CD) sub-micron to ≥ 2.0µm

-

Tighter specifications can be supported on both lines and contacts

-

Please contact us via our RFQ form for further information on individual specifications required

| Substrate Size | Quartz | Soda-lime | Borofloat | Substrate Thickness |

|---|---|---|---|---|

| 3" x 3" | YES | YES | NO | 0.06" |

| 4" x 4" | YES | YES | NO | 0.06"QZ & SL; 0.09" QZ only |

| 5" x 5" | YES | YES | NO | 0.09" |

| 6" x 6" | YES | YES | NO | 0.12"QZ & SL; 0.25" QZ only |

| 7" x 7" | YES | YES | NO | 0.12"QZ & SL; 0.15" QZ only |

| 7.25 R | YES | YES | NO | 0.15" |

| 8" x 8" | NO | YES | NO | 0.12" |

| 9" x 9" | YES | YES | YES | 0.12" |