ALPHA TrueHeight Preforms have the advantage of flexible spacer positioning.

Strategic locations can be chosen to ensure consistent bondline thickness. The architecture of the design not only addresses the BLT requirement but also reduces the opportunity for voiding. The design minimizes areas where gases can be trapped during the reflow process compared to other technologies. ALPHA TrueHeight Preforms can also be flux coated, with a wide selection of fluxes available.

Features

- BLT control of 0.075mm and higher standard.

- Prevents bondline tilt.

- Various preform sizes, shapes and thicknesses available.

- Preforms available in all standard solder and 4N purity alloys.

- External flux coatings available for traditional and low voiding applications using non-tacky flux formulations.

Bondline Thickness and Tilt Control

ALPHA TrueHeight® Solder Preforms TDS English

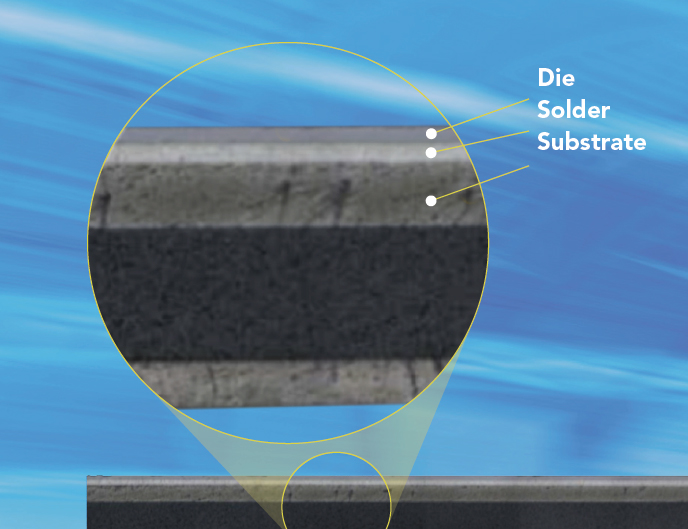

ALPHA TrueHeight Solder Preforms prevent die tilt and deliver consistent bondline thickness.

ALPHA TrueHeight Preforms can be tailored for different applications. The preforms are available in customized shapes and thicknesses, with embedded spacer(s) that address all major applications requiring 75µm bondline and above.

ALPHA TrueHeight Preforms have built in spacers that can be strategically located to ensure consistent bondline thickness and minimal die tilt. The design architecture not only addresses the BLT requirement but also reduces opportunities for voiding. Gases aren’t prevented from escaping the structure itself. ALPHA TrueHeight Preforms can be flux coated with a wide range of fluxes designed for your specific application.