Product Overview

ALPHA OM-550 HRL1 is a high reliability, low-temperature solder paste. The HRL1 alloy in this paste has a melting point significantly lower than SAC305 which will help to increase production yield and reduce component warpage.

Together, the flux and alloy combine to make a product that has the characteristics of a traditional solder paste used in high end CPUs but with the ability to reflow at lower temperatures therefore minimizing post reflow warpage induced defects.

Product Features

- Low reflow peak temperature of 185 to 195 °C for mixed alloy process

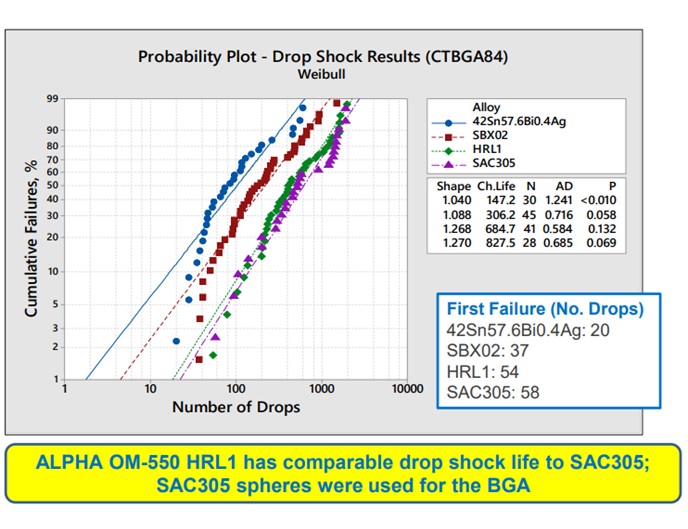

- Compatible with HRL1 alloy for comparable mechanical performance to SAC305 in the right application

- Reduction of warpage induced defects compared to SAC reflow process

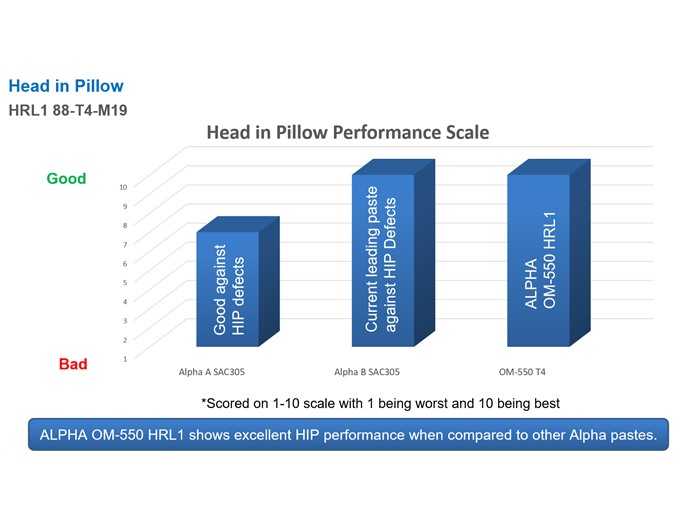

- Excellent NWO & HiP Performance

- Fine Feature Printing/Reflow capable

Reduction of Warpage induced defects

Next generation processors have been increasing in size to provide more processing power and meet the ever demanding need of the market. The desire for functionality and portability has inevitably caused processors to be as thin as possible.

Increases in package footprint and thinning of package profiles has the side effect of warpage induced defects especially traditional SAC305 reflow processes.

Warpage induced defects such as Non-Wet-Open and Head-in-Pillow can be mitigated by adopting solder paste technology such as ALPHA OM-550 HRL1.

Compatible with HRL1 low temperature alloy

Advancement in next generation CPU designs have forced the evolution of low temperature solder alloy technology.

ALPHA OM-550 paired with HRL1 alloy further enhances the mechanical performance of low temperature technology to meet the growing demand. ALPHA OM-550 HRL1 offers comparable mechanical performance to SAC305 in terms of drop shock with 54 drops to first failure for HRL1 and 58 drops to first failure for SAC305.

Additionally, thermal cycling reliability in the right application offers enhanced performance with HRL1 relative to SAC alloys.