Product Overview

ALPHA CVP-520 is designed for near eutetic low temperature alloys such as SnBi0.4Ag to enable peak reflow profiles between 155°C and 190°C. The flux residue is clear, colorless, and provides excellent electrochemical reliability.

The carefully selected alloy in ALPHA CVP-520 offers the lowest melting point, lowest pasty range during melting and re-solidification, offering maximum resistance to thermal cycle based fatigue in traditional low temperature alloy applications. The alloy also yields very low voiding BGA solder joints, even when a traditional SAC alloy sphere is used.

All components used with SnBi solders must be lead-free to eliminate the formation of tin/lead/bismuth intermetallic which has a melting point under 100ºC.

Product Features

- Eliminates 2nd or 3rd reflow cycle when temperature sensitive components are used

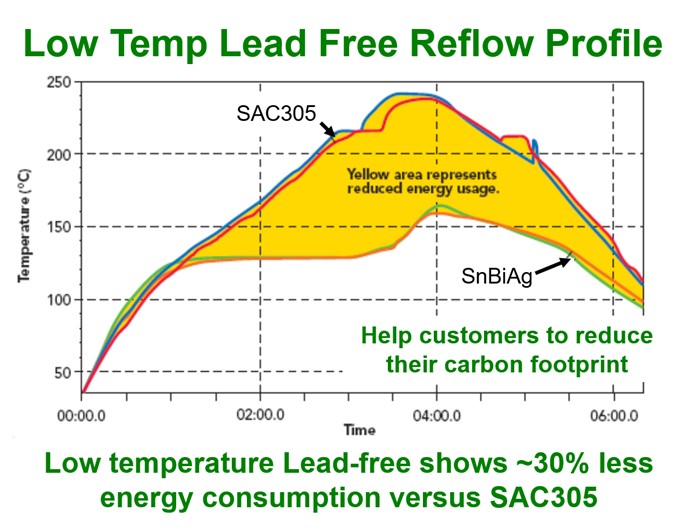

- Low temperature alloys reduce energy consumption in reflow ovens versus standard lead free alloys

- 8-Hour stencil life

- Lower reflow profiles enables the use of low Tg substrates

- Compatible with either nitrogen or air reflow

Low melting point provides significant process advantages

Low temperature lead-free solder paste (i.e. <200 °C peak reflow temperature) has 3 significant process advantages such as elimination of a Wave or Selective Soldering process step in multiple reflow applications while preventing damage to temperature sensitive components and connectors.

ALPHA CVP-520 also offers significant reduction in reflow process cycle time and energy consumption which can translate into reduction of carbon footprint.