WHY - Sintering Die Top Attach

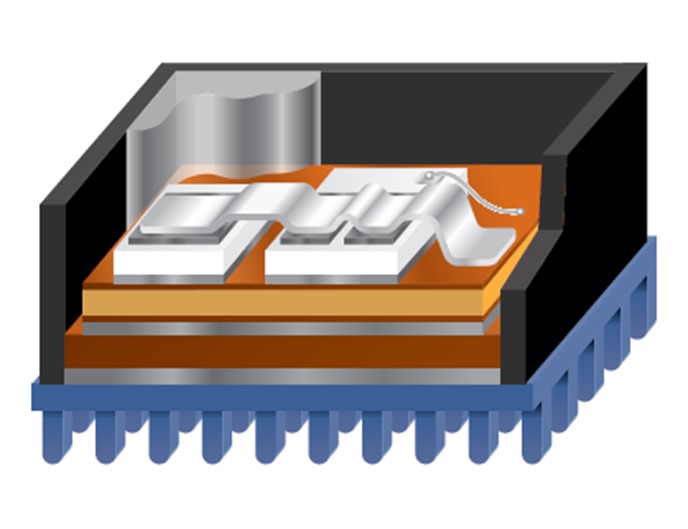

The reliability testing on previous generation power devices demonstrated that the two main causes of failure are die attach solder fatigue and wirebond lift off, both the result of the strain caused by material CTE differences and the temperature excursions during switching.

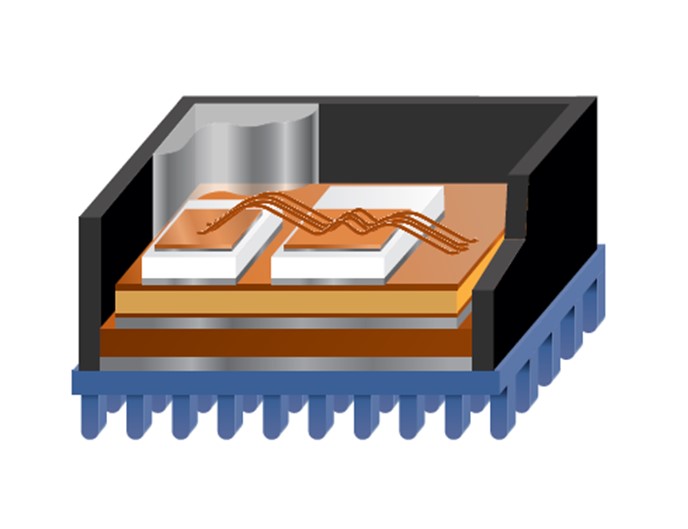

The implementation of sinter material die attach addresses the solder fatigue issue, but the true ability of sintering to extend product endurance is only realized when traditional aluminum wirebond failures are eliminated.

HOW - Sintering Die Top Attach

In the new generation of devices, the topside attachment to the die uses sintered clips or sintered copper foils. Clips are typically constructed of silver plated copper or pure silver, laminated and sintered to the die topside. Alternatively, a copper foil can be laminated, then sintered to the die topside, supporting the increased reliability and current density of copper wirebonds. Clips and foils, laminated with ALPHA Argomax film, enable an assembly ready interconnect for a fully sintered solution.

Products

| PRODUCT TYPE | PRODUCT NAME | COMPATIBLE SURFACE FINISH | PRODUCT APPLICATION METHOD | END APPLICATION |

|---|---|---|---|---|

| Engineered Sinter Product | ALPHA Argomax 6500 Bond Pad | Ag, Au, Cu | Pick & Place | Die Top Attach |

| Sinter Film | ALPHA Argomax 8020 Film | Ag, Au | Direct Transfer Film | Die Attach, Die Top Attach, Spacer Attach |

| Sinter Film | ALPHA Argomax 2010C Paste | Ag, Au | Die Attach, Die Top Attach | |