Product Overview

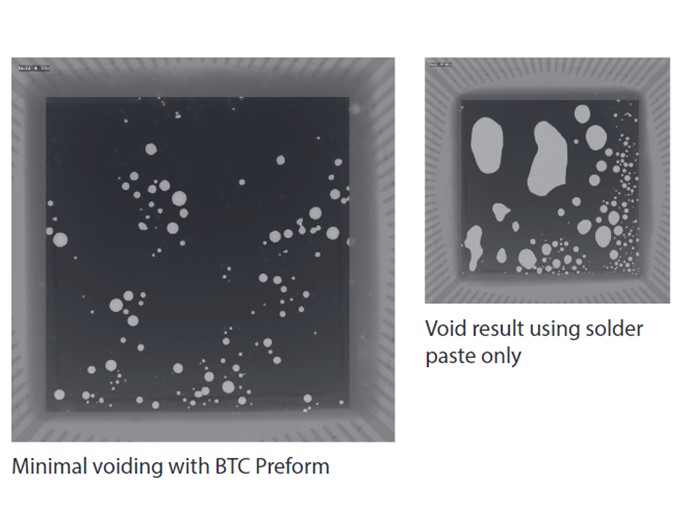

ALPHA AccuFlux BTC-578 technology is a precision controlled micro-flux coating on solder preforms. The chemistry was designed specifically to produce lower void results at the thermal/ground interface of Bottom Terminated Component packages such as QFN, QFP, and D-Pak.

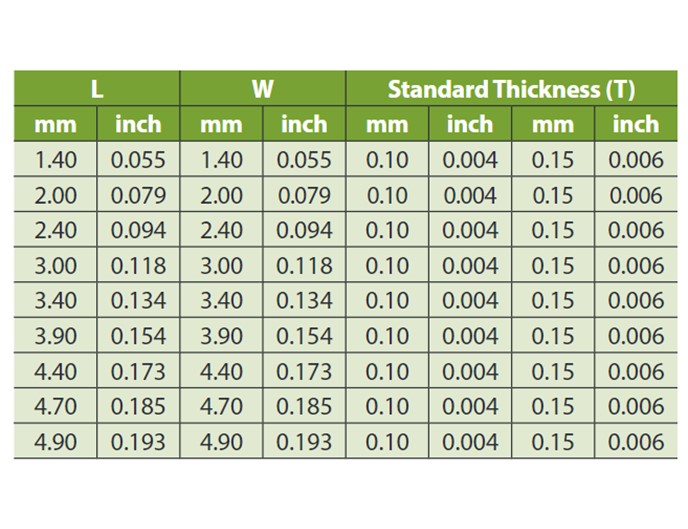

Incorporating ALPHA AccuFlux BTC-578 flux coated preforms and solder paste with an optimized stencil design results in minimal to non-detectable flux residues, meeting the most demanding electro-chemical reliability requirements. This technology can easily be implemented into an existing SMT circuit assembly process.

Product Features

- Efficient heat dissipation through consistently low voids

- Enhanced process stability and predictable reliability through repeatable void distribution

- Maximizes mechanical integrity through increased solder volume

- Enhanced electrochemical reliability on shrinking component packages through low flux residue

ALPHA AccuFlux BTC-578 Preform Technical Bulletin English

Void Reduction Strategy for Bottom Termination Components (BTC) Using Flux Coated Preforms Paper English

Attacks the most challenging void performance

With power requirements for BTCs increasing, component manufacturers are designing smaller device packages that require less voids for optimal performance. Consistent void results are often challenging to obtain not only from board to board, but from component to component. OEMs often require 100% X-ray inspection to manage random void performance under BTCs. This often causes countless hours of rework resulting in higher costs. ALPHA AccuFlux BTC-578 preforms are a proven method for providing consistent low void results with very high confidence.