Product Overview

ALPHA Exactalloy Solder Preforms offer increased solder volume for joint reliability, reduced flux residue for improved electrical reliability, and void reduction under component thermal pads.

The convenience of Tape & Reel packaging allows preforms to be implemented into standard SMT processes. A wide variety of standard preform sizes and alloys are available off the shelf. Designed to match industry standard chip capacitor sizes, this enables standard nozzles for placement, making the implementation near seamless. Our labs conduct extensive testing to ensure high pick and place rates for all preform sizes from 1406 down to 0201.

Product Features

- Selective solder volume increase for solder joint strengthening

- Enables 100% hole fill

- Reduces flux residue for ICT

- Eliminates rework and inspection after reflow

- Low temperature compatible

Provide 100% hole fill to through-hole components

Intrusive reflow is often used to assemble through hole components in an SMT process. However, often solder paste alone cannot produce adequate solder volume to allow for 100% hole fill. Placing an ALPHA Exactalloy solder preform into the solder paste aperture surrounding the pin and hole realizes 100% hole fill every time.

Overcome solder volume deficiencies on PCB assemblies

Our solder preform tape & reel packaging provides a time-to-market advantage, solving your solder volume issues during assembly verification. With electrical components' sizes becoming even smaller, printing sufficient amounts of solder paste onto miniaturized, overpopulated PCBs has become increasingly challenging.

ALPHA Exactalloy Tape and Reel Preforms are specifically designed to overcome these solder deficiencies, enhancing the solder joint strength and reliability.

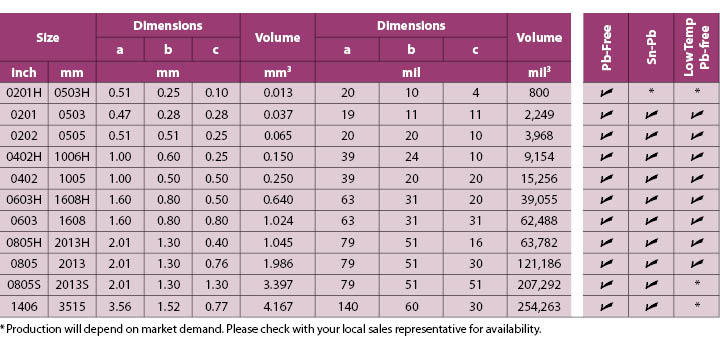

ALPHA Exactalloy Tape & Reel Size Chart