Product Overview

NOVAFAB NANOTWIN Cu is a high-purity copper electroplating process which produces a <111> oriented deposit with a high fraction of nano-twinning. It is specially formulated for use in the fabrication of pillars or pads for wafer level packaging applications that require hybrid bonding. This system enables low temperature, high reliability copper to copper interconnects for die-to-die (D2D), die-to-wafer (D2W), and wafer-to-wafer (W2W) bonding.

NOVAFAB NANOTWIN Cu is a ready to use solution designed for use with soluble or insoluble anodes. The NOVAFAB NANOTWIN Cu process yields excellent thickness distribution over whole wafer surface for consistent electrical properties and bondability.

Features

- Novel one-part additive system

- <111> oriented crystal structure

- High nanotwin density

- Excellent process stability

- Wide operating window

- High purity

For consultation with one of our experts and access to detailed technical data , please fill out and submit the contact us form.

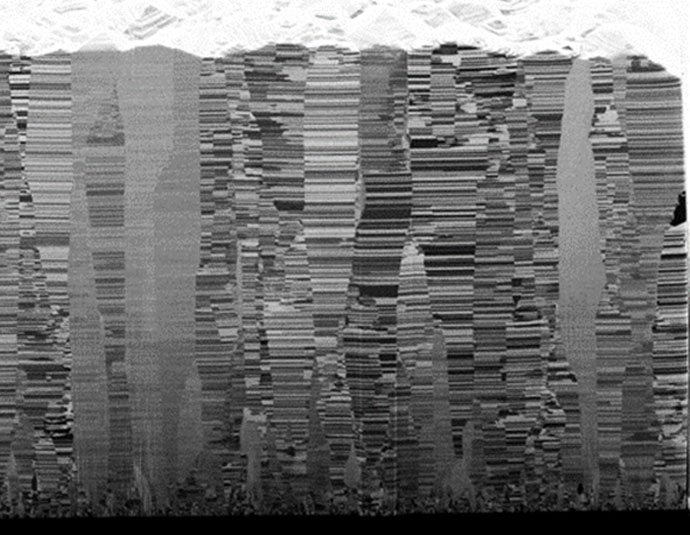

Highly Nanotwinned Columnar Copper

Nano-twinned Cu (nt-Cu) demonstrates superior mechanical and electrical properties. High performance applications are driving I/O pitch reduction and I/O density increases leading to solder removal at reduced pitch sizes.

NOVAFAB Nanotwin Cu

|

Product Name |

Cu Packaging Solution |

Cu Process Feature |

Feature-Property Benefit |

|---|---|---|---|

|

NOVAFAB NANOTWIN Cu |

Hybrid Bonding |

Nanotwin |

KV Low |